Roller or roller-element bearings work using the same principle as the ball bearings and serve the same principle function, which is to support load and transfer movement, only using a different design. The main difference between the two types of bearings is their shape and construction.

The ball bearing uses balls, while the roller bearing uses cylinders, such as cross roller bearings and linear roller bearings.

Depending on the roller bearing type, it can contain single or double rows of rollers. This also depends on the application and the load size the bearing is expected to support.

Types of Roller Bearings

Roller bearings serve many applications across various industries with varying requirements. As such, the design and features of the bearings have evolved to ensure that bearings can provide the best performance in each of those applications. Some of the available types of roller bearings from TFC include;

Single-row roller bearings

Single-row roller bearings only have one row of rolling elements. They have a simple, non-separable design and angular roller bearings that can only handle axial loads in one direction. This type of roller bearing is an excellent option for high-speed application. However, if the rolling body load action and the radial load action lines are not on the same radial plane, single-row bearings must be mounted in pairs when subjected to pure radial loads.

Double-row roller bearings

Double-row roller bearings have two sets of rolling elements, allowing them to carry bi-directional radial and axial loads. However, the axial displacement of the shaft can be restricted, as well as the casing within the bearing’s axial clearance. Double-row angular contact bearings provide better rigidity, enabling them to endure overturning moments or tilting effects besides the enhanced rigidity. Other advantages of double-row bearings include high load capacity and compactness.

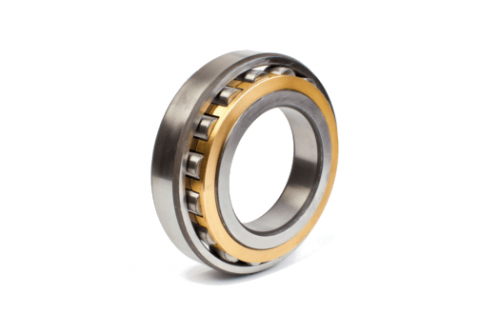

Spherical roller bearings

These are roller bearings capable of handling both heavy radial and thrust loads. They feature an outer and inner ring and a set of spherical rollers that are held between the two rings.

In this setup, the inner ring has two raceways and the rollers are shaped to match the raceways, supplying stability and support to the load.

Spherical roller bearings are unique because they are designed to accommodate misalignment and are commonly used in applications with concerns about shaft misalignment and deflection. Spherical roller bearings are most used in the industrial and construction machinery industries.

Tapered roller bearings

Tapered roller bearings also have a unique design highlighted by a different diameter at each end, giving the bearing a tapering appearance, hence its name. The design allows for greater contact surface between the inner and outer races, making them ideal for handling heavy radial and thrust loads simultaneously.

Tapered roller bearings are commonly used in the automotive and industrial machinery industry. They are also ideal for use in applications where there is a need for precise shaft alignment and support for heavy radial loads.

Partner with TFC

As a leading supplier of all types of bearings, including ball bearings and other components like springs and fastening options, TFC can supply roller bearings to vendors and private clients regardless of the quantity while ensuring the best quality.

We draw from years of experience and dedication from our parent company, AFC, to supply the best C-Class and customised components to our vast customer base, which includes some of the leading companies in various industries.

With our firm understanding of our catalogue, we are dedicated to meeting and exceeding customer expectations and helping customers bring their projects to life through our dedicated technical team that can help customers with customised requirements get prototypes and transition into total production seamlessly.

Follow us