Smalley Wave Springs

TFC is the sole UK & leading European supplier of Smalley Wave Springs. Smalley and TFC have built a reputation for unsurpassed quality and an expert, collaborative engineering team.

With decades of experience, we’ve been a supplier of high-quality Smalley Spirolox® Retaining Rings, Snap Rings, and Wave Springs. Smalley is the leader in the manufacture and development of these products with a standard range consisting of 10,000 parts stocked in carbon and stainless steel.

We’d love to hear from you!

Just fill out the form below and we’ll be in touch or call us on 01435 866 011

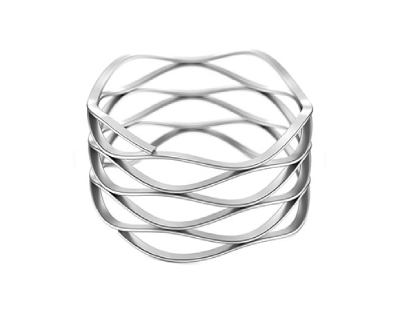

Smalley Wave Springs

- Wave springs reduce spring height by 50%

- Same force and deflection as ordinary coil/compression springs

- Wave springs fit tight radial and axial spaces

- Over 4,000 standard springs in carbon and stainless steel (.188″ to 16″, 5 mm to 400 mm diameters)

- No Tooling Charges™ on custom designs (.118″ to 120″, 3 mm to 3000 mm diameters)

- Exotic alloys available

Innovation for Over a Century

Smalley has evolved to become the world leader in the manufacturing and development of Retaining Rings, Spirolox Retaining Rings and Wave Springs.

The Smalley product line consists of 10,000 standard parts stocked in carbon and stainless steel, as well as custom design solutions in exotic alloys or customer, specified dimensions. All of Smalley’s standard catalogue parts are manufactured using raw materials and rust preventatives that are in compliance with the RoHS and REACH directives when supplied without any additional plating/coatings.

When time is of the essence, Smalley’s No-Tooling-Cost™ manufacturing process allows for fast prototyping and economical production. Our engineers are available for design consultations, providing our customers with a full range of resources to ensure their application contains the most cost-effective and appropriate solution possible.

Product range

Smalley Wave Springs

coil springs, with up to 50%

less axial space

for even load distribution

coil springs, with up to 50%

less axial space

for even load distribution

eliminating errors in stacking individual springs and

reducing assembly time.

eliminating errors in stacking individual springs and

reducing assembly time.

with an accurate, predictable

spring rate.

This increases the spring’s functional thickness,

leading to increased loading.

Coil Springs

Coil springs serve as essential components in a wide range of mechanical systems. They absorb shock, maintain force, and facilitate controlled movements. You can find them everywhere, from car suspensions to trampolines to garage doors and even pens and locks.

Since the invention of the commercial coil spring, believed to be in the 18th Century, their design has stayed consistent. They are helical-shaped mechanical devices made out of wound metal. They store potential mechanical energy and release the energy to absorb shock.

Coil springs are made by winding a strand of wire using continuous turns to form a helical coil. Just like the basic design, the purpose of the spring also hasn’t changed much. Still, spring applications have expanded, forcing manufacturing to make springs in different sizes, types, and materials.

At TFC, we have years of experience supplying specialist spring solutions with our partners, Smalley, to clients in different industries. Our close relationship with the manufacturer enables us to identify the perfect spring for any solution and smoothly integrate it into your supply chain.

Already know what springs you need? Speak to us today

How Coil Springs Are Made

The material and process used to make a coil spring depend on whether the facility is a high or low-production facility. Our partners use the most advanced coil spring manufacturing methods and equipment to keep up with our high-quality assurance and give our customers the highest quality springs without compromise.

Coil spring materials

The most commonly used materials in making coil springs are high and medium carbon steel, chromium, vanadium steel, chromium silicon steel, and other grades of stainless steel, nickel, and copper alloys. We can help you match the type of coil spring material with your application and seamlessly incorporate it into your VMI or bespoke order.

Cold winding

Coil springs can be made through cold winding or hot winding. In the case of cold winding, the wire will only work if it has a diameter of 0.75 inches or 18mm or less. The manufacturing process typically follows these steps;

- Heat treatment – The wire is heat-treated to reach its highest strength level.

- Making the coil – Manufacturers can use one of two methods to produce coil springs. The first one is the mandrel method, which uses a winding machine, a lathe, or a hand crank machine. This method is ideal for small production units that don’t have a high output. There’s also the CNC spring coiling method. It is more complex and intricate and produces higher-quality springs. The machine has components that efficiently feed, wind and configure the coils.

Hot winding

The wire thickness required for hot winding can be thicker. It can vary between 3 inches or 75mm up to 6 inches or 150mm. In hot wining, the wire is heated to up to 900°C (<1660°F), so manufacturers can work with a larger diameter wire.

- Coiling – The heated metal can be coiled using the mandrel method, which uses the same process as coil coiling but requires greater care. You can also use a CNC machine that controls the rotation of the mandrel and pitch distance.

- Cooling – The next immediate step is to cool the wound coil as quickly as possible through quenching. Several quenching methods can be used. Oil quenching is the most popular. The purpose of cooling is to harden the coil’s material and minimize the formation of thermal and transformational gradients that could cause cracking.

- Stress relief – The stretching of the wire when coiling disturbs the natural balance of the molecule within the material, leaving the spring with residual stress. If the stress is not relieved, the spring can have defects, cracks, and a shorter lifespan. Stress relieving is performed by heating the spring to a level below its deformation so the wire becomes malleable but doesn’t melt. The heating process is followed by a slow return to room temperature to allow the molecules to rearrange.

- Finishing – Finishing depends on the design of the spring. Finishing includes the shape, coating, setting of the pitch, and strengthening of the coil. Depending on the client’s needs and the application of the spring, we can grind the spring to flatten the ends, shoot peening to change the mechanical properties of the coil spring and smooth the surface. We can also adjust the pitch and length of the spring and apply the necessary coatings to improve its aesthetic appearance and durability.

Types of Coil Springs

Coil springs can be classified as either coil or non-coil, depending on the general design of the spring. While all the springs share the helical design, some have unique features that distinguish them from the rest. The most common coil springs we supply include;

Volute coil springs

This type of compression coil spring is made in the shape of a volute, better known as a cone. Volute springs are used in applications involving heavy loads. They can withstand more pressure than other springs because of their unique shape.

When subjected to heavy loads, volute coil springs become stiffer on the edges and distribute the weight downward and outward.

Arc springs

These are also coil springs, also known as bow springs. Arc coil springs were initially developed for use in automotive and mechanical drive trains. They feature an arc shape and don’t run entirely straight from one end to the other. Instead, they have a curve in the middle, creating an arc shape. The spring is connected to two objects, which it pulls together.

Variable springs

Also known as progressive rate springs, this type of spring comes with a variable rate because of the different distances between their turns. Unlike traditional coil springs with a linear force-displacement relationship, variable springs exhibit a non-linear force characteristic.

Torsion springs

Torsion springs are designed to withstand or resist twisting actions. The best example of a torsion spring is in the traditional mousetrap. The torsion coil spring retains its mechanical energy when twisted along its axis. They then release this energy when the lock is removed.

Types of Coil Spring Ends

Besides the main factors of the coil springs, you also need to consider the type of ends of the coil spring. We supply our coil springs in four main ends;

- Closed-end – This is the most common form. They have flat tips that are in contact with the adjacent coil for better stability.

- Square end – The end of the spring has been ground. These end types produce springs with greater deflection than open-end coil springs.

- Pigtail coil spring – The spring’s last coil has a smaller diameter than the rest of the coil. It makes it possible to attach the spring to a mechanism using a bolt or screw.

- Open-end – These are continuous springs where the coil continues on its pitch. Sometimes, these are referred to as tangential coil springs.

Can’t find what you’re looking for? Get in touch!

Compression Springs

Compression springs are the most common type of springs and have various applications. There are different types of compression springs designed for multiple applications and loads. Working closely with our manufacturing partners, Smalley, we specialise in wave springs, a unique compression spring type. Like ordinary springs, the wave spring comes in various types and configurations to suit different applications and user requirements.

Already know what springs you need? Speak to us today

Types of Compression Springs

Our extensive range of compression wave springs is designed for varying applications. Our range of wave compression springs includes;

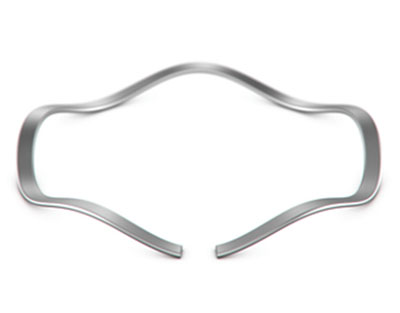

Gap and overlap compression spring

This is a versatile type of wave compression spring with many applications. It is ideal for short deflections and low-medium forces. It’s known for its precision and dependability.

This type of Smalley wave springs allows for radial expansion or growth in diameter within the cavity. The gap spring has a gap at the end, while the overlap has overlapping ends. In the latter type of spring, the ends can move freely circumferentially as the spring’s outer diameter grows during compression.

In gap wave compression springs, the gap moves closer during deflection. This feature also keeps the springs from tangling as much in the packaging. In applications, both options will function the same way. The free ends of this type of compression spring allow the outer diameter of the spring to contact the bore without binding as the spring is compressed.

Crest-to-crest wave compression spring

This type of compression spring is pre-stacked in series. It decreases the spring’s rate proportionality to the number of turns, making the spring ideal for applications requiring low-medium spring rates and large deflections with low-medium forces.

The design of the springs eliminates the need to keep the wave crests aligned. When using crest-to-crest wave springs, there’s no need to use a key locating device, and inserting a shim between the individual springs is not necessary. Another unique benefit of this type of spring is that the wave peaks hold their configuration because the spring is integrally formed.

Crest-to-crest springs are a formidable replacement for helical compression springs. They develop similar forces but only occupy half or less axial space. They are perfect for applications that have strict space constraints. They maintain the same force and load specifications as conventional round wire springs.

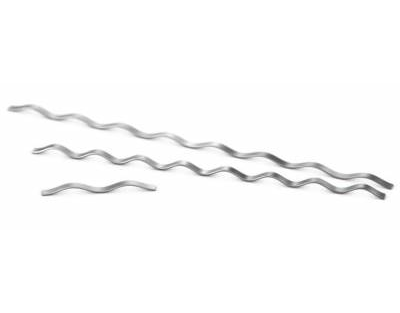

Crest-to-crest with optional shim ends

Crest-to-crest wave springs come in various configurations. They are also available with squared-shim ends.

The shim ends provide a 360-degree contact surface, which is not the case with plain ends. The shim-ends distribute weight more evenly when under load to the adjacent components. Think of it as double-disc grinding springs for a flat surface.

Shim-ends are used to affix springs to the mating components. They act as a flat locating surface that can be attached by various methods in the assembly.

Nested compression springs

Nested wave compression springs are pre-stacked in parallel from one continuous filament of flat wire. Nested compression springs eliminate the need to stack individual springs for higher loads. With nested springs, the spring rates increase proportionally with the number of turns.

The spring can exert tremendous force and still maintain the precision of a circular-grain wave spring. In most cases, nested springs replace Belleville springs. They are most suited for applications where high but accurate forces are vital.

WAVO® springs

These are springs produced from round-section wire. They provide higher loads while maintaining the accurate loading that wave compression springs offer. Wavo Springs are also an alternative to Belleville Disk Springs. They provide similar loads but have more accuracy and a predictable spring rate.

The different types of compression springs are designed to suit various applications and structural demands. At TFC, we have different wave compression springs to suit every application and user requirement while providing superior accuracy, spring rate and weight distribution.