TFC Ltd – Vendor Managed Inventory, Industrial Fixings & Fastener Supplier

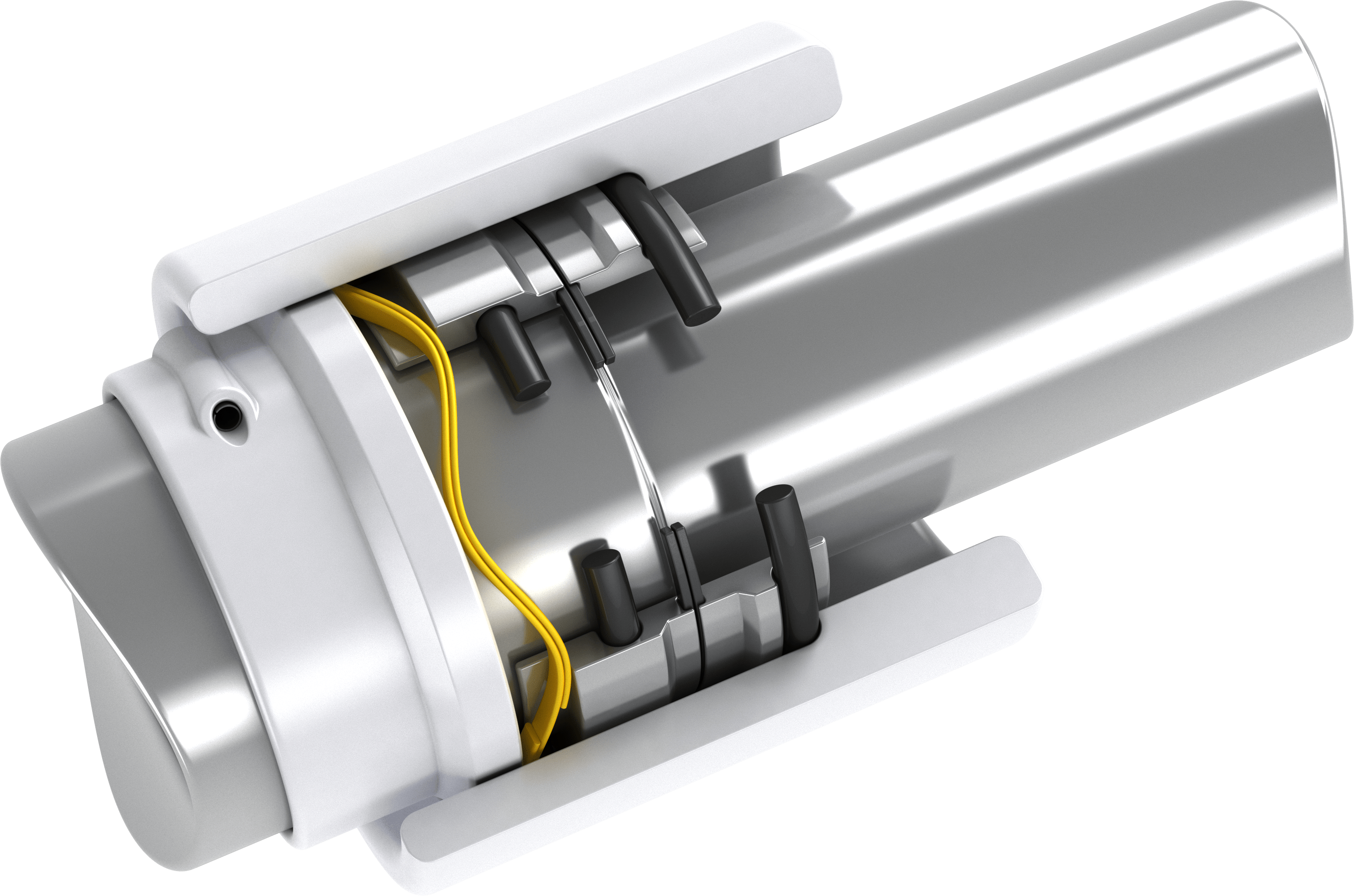

Nested Spirawave® Springs

Nested Spirawave Springs are multi-turn, flat wire wave springs coiled in parallel, available in two-turn or three-turn configurations. They can replace stacks of single-turn wave springs, eliminating errors in stacking individual springs and reducing assembly time. Nested wave springs are specified for applications requiring medium-to-high loads and short deflections.

Can’t find what you’re looking for?

Nested Spirawave® Springs Range

Industrial Springs

Since civilisation, heavy-duty industrial springs have been a substantial part of the engineering and construction world. Although the design of the industrial spring has changed dramatically to become what we have at TFC, its primary purpose remains the same: providing flexibility and stability in large and small structures, equipment, and machines.

We have many distinct heavy-duty industrial spring designs to suit different applications and equipment. Our springs are made from different materials to ensure they can flourish in different application environments and deliver the best performance.

Our Range of Heavy-Duty Industrial Springs

TFC is the sole UK and leading European supplier of Smalley Wave Springs and Retaining Rings, renowned for high-quality Smalley Spirolox® Retaining Rings, Snap Rings, and Wave Springs. With a standard range of 10,000 carbon and stainless steel parts and a No-Tooling-Cost manufacturing process for fast prototyping, TFC’s expert engineering team offers design consultations to ensure the most effective solutions for your applications.

What is an Industrial Spring?

Springs come in many sizes, dimensions, and configurations. An industrial spring is no different. It’s a spring manufactured from metal, metallic alloys, or non-metallic materials to provide support, mobility, and flexibility for various industrial applications and machinery.

Industrial springs are an integral component of all types of machinery, from massive CNC milling machines to watches, telephones, and consumer electronics. The springs can be manufactured through prototyping technologies such as 3D Printing or CNC machining.

Given the massive applications of these types of springs, making informed decisions when choosing the right industrial spring is crucial. The springs are mechanical devices that play a critical role in the performance of the more extensive set-up. They store just the right amount of energy and force to restore equilibrium when required. Because these springs have vast applications, ensuring the right one for your working mechanism is essential.

Types of Heavy-Duty Industrial Springs

Industrial springs are classified into three main categories;

These types of springs are characterised by their resistance to axial compressive forces. They are the most common and effective energy storage springs on the market.

As the name suggests, this type of spring compresses or shortens when force is applied, storing energy in the process.

The energy is released when the spring tries to stretch back to its original length, pushing back against the load. Our Wave Springs are an excellent example of a compression spring.

Extension or tension springs are terms used to describe springs that can resist tensile forces or pressures that try to pull them apart. They are springs that are initially coiled with tension, and when they’re lengthened, they attempt to return to their initial shape, resulting in a pulling force. The springs can be easily linked to elements that need to be kept together by the force of the spring because they have a hook or a loop at the ends.

Torque-resistant applications require the use of torsion springs. These helically wrapped springs have arms at the ends and rotate around their central axis. The arms are attached to external components, which apply pressure on the spring. It’s important to note that a torsion spring is only loaded in one direction, causing the diameter of the spring to shrink.

Types of Industrial Springs We Offer

TFC carries an extensive range of Smalley industrial springs for various applications and machines. We also offer engineering services to clients looking for customised springs for unique applications. Our standard industrial springs include the following;

Nested Wave Springs – YNSSB (Metric)

This is a flat wire wave spring with multiple turns coiled in parallel to produce higher forces, which increase proportionally to the number of turns. This nested wave spring is available in a standard series, but the single stacks of single-turn wave springs can be replaced in applications that require higher loads than single-turns can produce.

Nested Wave Springs – YNSSR (imperial)

This is also a flat wire wave spring with multiple turns coiled in parallel to produce higher forces. The spring can be engineered to produce higher forces by adding a number of turns, making the spring highly adjustable to match various engineering requirements.

Coil Springs

We have years of experience supplying heavy-duty industrial coil springs and specialist coil spring solutions to various clients. We have an extensive range of wave springs, standard compression springs , tension springs, torsion springs, wire shapes, flat springs, die springs and disc springs.

We are your one-stop shop for all your industrial coil springs needs. Our vast experience and selection of options mean we can serve the needs of every client no matter how demanding, even when their needs are specialised.

Linear springs

Heavy-duty industrial spring applications are diverse, often requiring the design of the spring to adapt to the function. This is where our Smalley linear range springs into action. Unlike conventional helical springs that fit in circular cavities, these springs react in a long, straight line. Their unique design positions them axially whilst providing radial force between mating components.

Disc springs

We also offer various disc springs that conform to different DIN dimensions and load characteristics. The springs are fully deburred and have all rounded edges. The materials used to make the discs and washers are carefully considered to provide maximum support and performance in their respective applications.

Applications of Heavy-Duty Industrial Springs

We offer a comprehensive range of industrial springs. When choosing the right springs, we recommend that our clients consider the application of the spring to ensure the right spring for the task. Industrial springs have a wide range of applications in various industries, including;

Automotive industry

Industrial springs have multiple applications in the automotive industry, including in the suspension system, automotive valves, clutches and gear shifters.

Furniture industry

The furniture industry relies on industrial springs for their flexibility and elasticity, essential for designing ergonomic and comfortable furniture. These springs help achieve optimal comfort and support, particularly in leather sofas, providing both elasticity and stability for the user.

Electric vehicles

Industrial springs are also used in the manufacturing process of electric vehicles, particularly in stability and streamlining of operations.

Agricultural industry

Many industrial machinery, including tractors, combine harvesters and pumps, rely on springs. In most cases, the springs needed in this industry are large, strong and have a long working life. Stainless steel springs are preferred in this industry, and torsion springs are the most common.

Medical industry

Finally, the medical industry also has equipment that uses industrial springs. Torsion springs made from high-carbon steel are the most preferable in this industry. Applications of the springs include hospital beds, medical immobilisation devices, dental applications and wheelchair lifts.

Get in touch with a member of our team today for any enquiries about our heavy-duty industrial springs. Contact our engineering department for more details