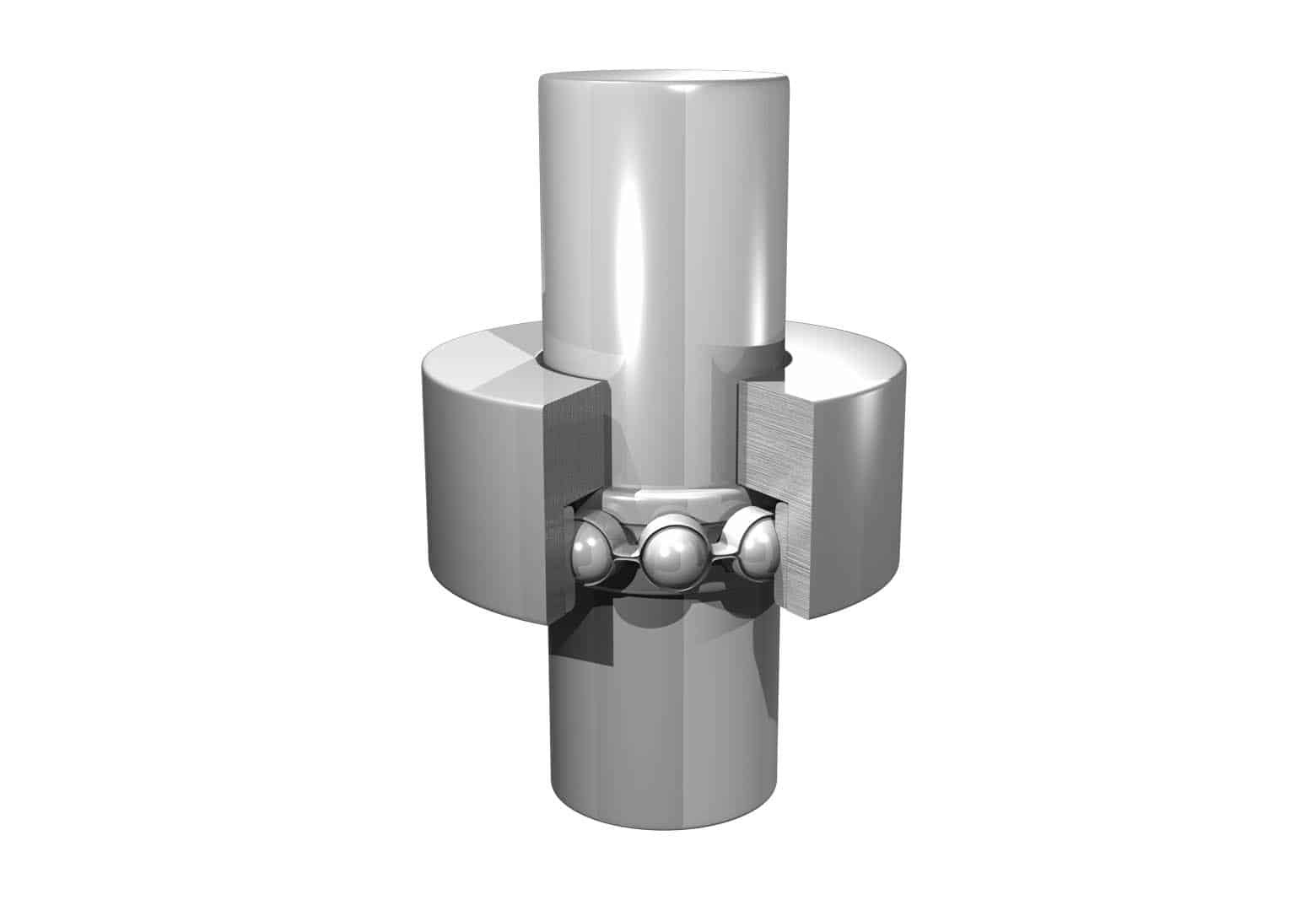

Ball bearings are designed to move freely. They have multiple parts that work together as a unit to facilitate movement and reduce friction. However, challenges can arise during manufacturing and assembly that can cause limitations with ball bearings, especially where loads are involved.

Preloading is the solution that designers and manufacturers have turned to. It is where a sustained axial load is provided to the bearing. Preloading prolongs the bearing life and, consequently, the equipment.

Already know what springs you need? Speak to us todayWhat are Bearing Preload Springs?

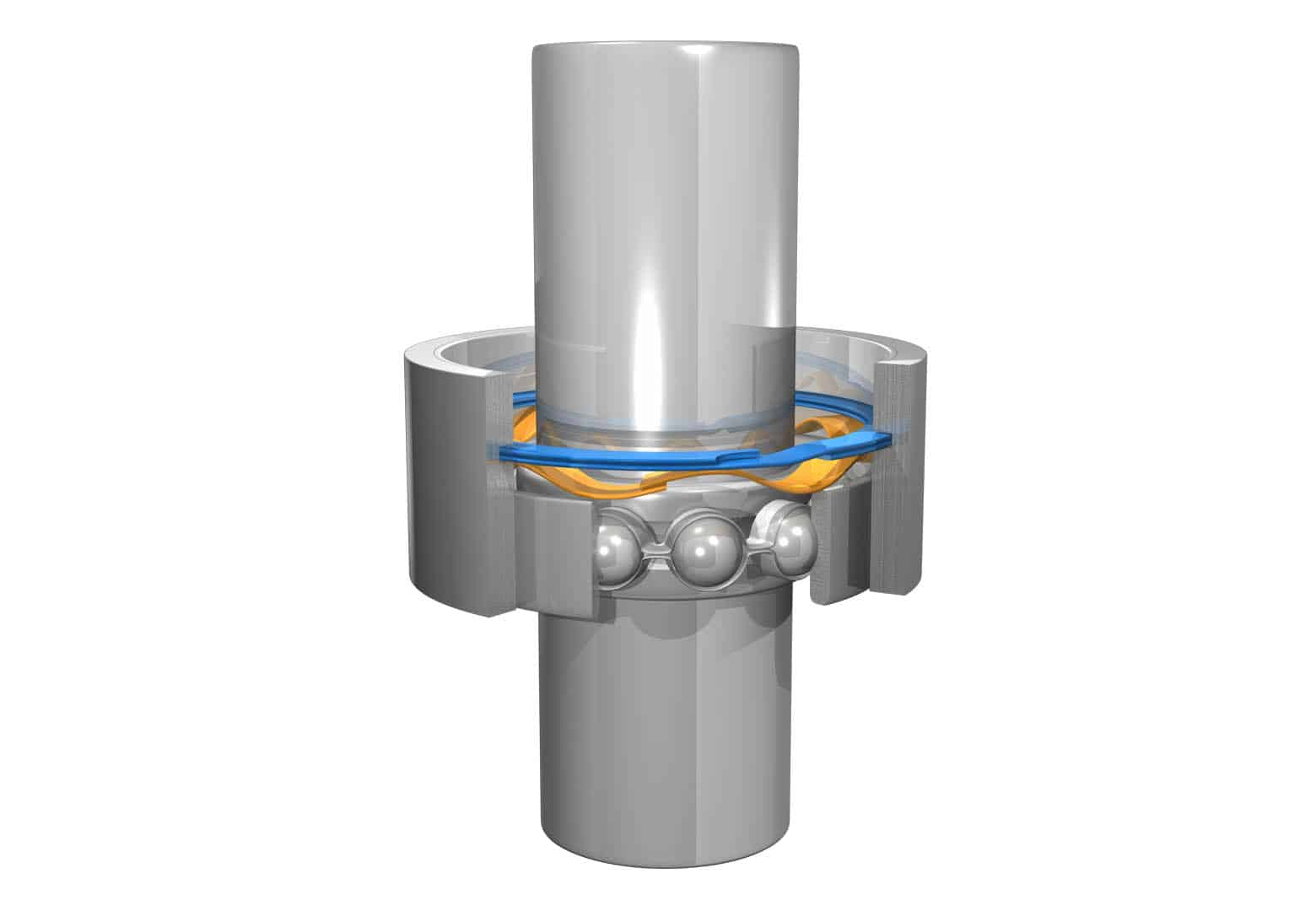

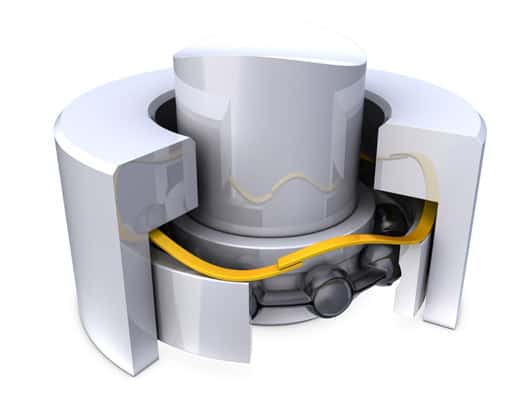

There are two ways to preload a bearing. The first is solid preloading, which is achieved by holding inner and outer races in place with a locking mechanism. The other, simpler, and less expensive method is spring preloading, which is achieved by applying a spring to apply a constant axial load on one side. This is where the Smalley bearing preload springs come in handy. Besides being more effective, bearing preload springs also help control play and maintain bearing functionality and longevity.

Advantages of Bearing Preload Springs

With the right bearing preload spring, you can maintain constant contact between the bearing and the bearing races. This eliminates radial and axial play, among other benefits. The springs achieve this without placing too much pressure on the ball bearing and causing unnecessary wear and tear.

TFC is a leading supplier of springs and the sole supplier of Smalley wave springs and bearing preload springs in the UK. We have many bearing preload springs to suit different applications and dimensions.

The bearing preload springs we supply are made from high-quality materials and technology. They are designed to fit into tight spaces with minimal dimensions, allowing manufacturers to make more compact, high-performance equipment without compromising its safety and longevity.

Another advantage of a bearing preload spring is it is critical in high-precision and high-speed applications. It eliminates the need for holding tighter tolerances. It also helps withstand high operating speeds.

The wave design of our bearing preload spring provides great load sharing between the bearings for reduced wear and tear. The design also means the complete assembly is quieter, even in high-vibration applications.

Why You Should Buy Bearing Preload Springs for TFC

TFC supplies industry-leading bearing preload springs from Smalley. The wave springs are designed to produce the right amount of pressure to minimise play and minimise bearing noise.

You can choose springs to provide light to medium pressure according to the requirements of the application in question.

We supply C-class bearing preload springs and provide customised solutions to customers with unique needs.

Customers requiring design or dimension changes can contact our technical team for enquiries and support in designing the required springs. We can help our customers create prototypes for the springs they need through our manufacturing partner, Smalley. Whether it is a custom order or one of the C-Class options, you are always assured of the best quality.

Wave springs can be made from different materials to match the needs of the application in question, in addition to their size and design.

TFC also offers supply management services, such as shipping out springs to our customers when and where they need them. If you’re looking for quality bearing preload springs delivered when you need them to cut back on your running costs, then we are the perfect solution for you and your operations.

Do you have some more questions? Get in touch!