TFC Ltd – Vendor Managed Inventory, Industrial Fixings & Fastener Supplier

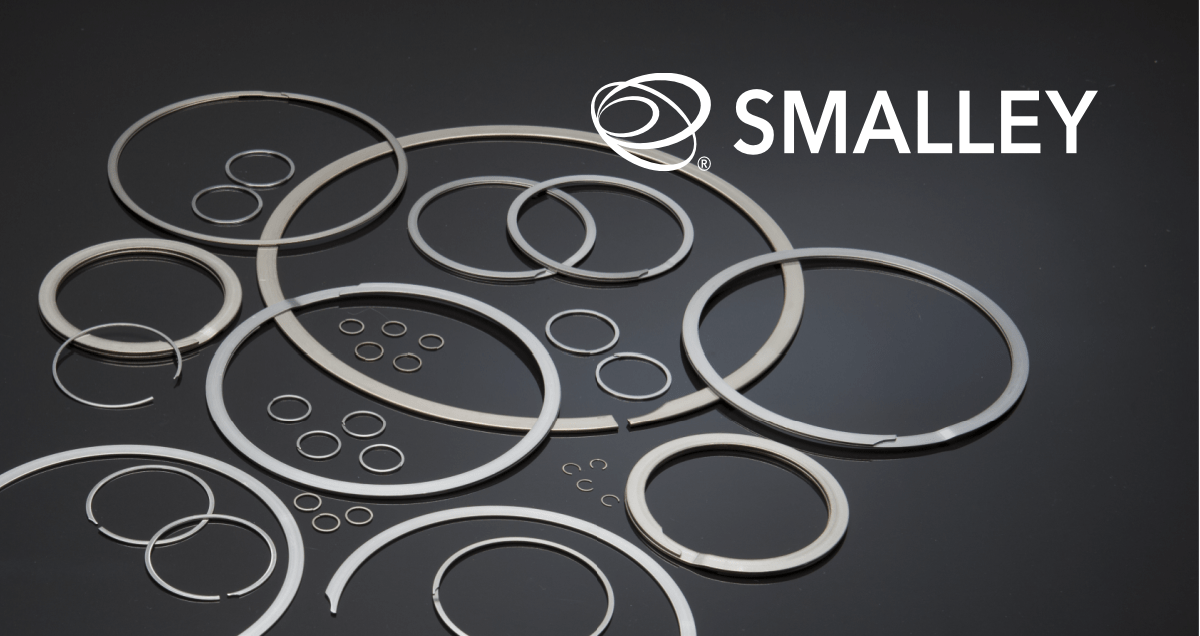

Wave Spring and Retaining Ring Solutions

TFC is the exclusive UK and a leading European supplier of Smalley products.

Quick Connectors

Fast, safe and reliable connector solutions for fluid and vapour handling systems.

Experts supporting your project every step of the way

Have our Technical team assist you with your custom design.

Welcome to TFC

TFC is one of the most trusted engineering groups in Europe. We deliver high-quality components from leading manufacturers according to required specifications, ensuring that clients achieve their design objectives.

Our customers receive innovative and comprehensive engineering support as well as certified products of the highest quality, ensuring the utmost confidence in the performance of the final product.

The Benefits of Collaborating with TFC:

- Expertise and knowledge in their respective fields.

- Customised solutions tailored to your requirements.

- Collaboration and ongoing support throughout the design process.

- Efficient and optimised design solutions.

- Assurance of quality and compliance.

- Cost-effective recommendations.

In short, utilising the TFC technical team ensures a well-designed and optimised product, saving time, effort, and resources in the design and development process.

Experts Supporting Your Project every step of the way.

Engineers at TFC will closely collaborate with you to deliver the most cost-effective and efficient technical support solutions that meet your needs. Whether it’s increased durability, working at higher temperatures, or greater versatility, we can provide you with a wide range of product options.

We regularly work on solving space-saving issues, providing alternative designs, and reducing parts by combining several components into one. Regardless of the challenge, our engineers will work with you to find the most effective solution.

Simon Ward

Technical Manager

Simon leads the UK technical team and specialises in the design and development of Smalley wave springs and spiral retaining rings. With over 25 years of experience, Simon develops bespoke parts for major clients around the world and across a wide range of industry sectors. He is now widely considered the leading authority on Smalley products.

Justin Lawrence

Applications Engineer

Justin specialises in the design and sale of wave springs, spiral retaining rings and quick connectors, designing custom products for a range of applications including oil & gas, automotive and medical. Justin has been with TFC for over 20 years, gaining further experience in the mechanical and industrial engineering sector.

Alicja Lorenc

Technical Support Engineer

Mechanical Engineering Services

TFC are the sole distributor of Smalley Wave Springs and Retaining Rings in the UK.

Our Mechanical Engineering Services

The TFC technical team quotes all off-the-shelf products before handing them to Smalley to fulfil the order.

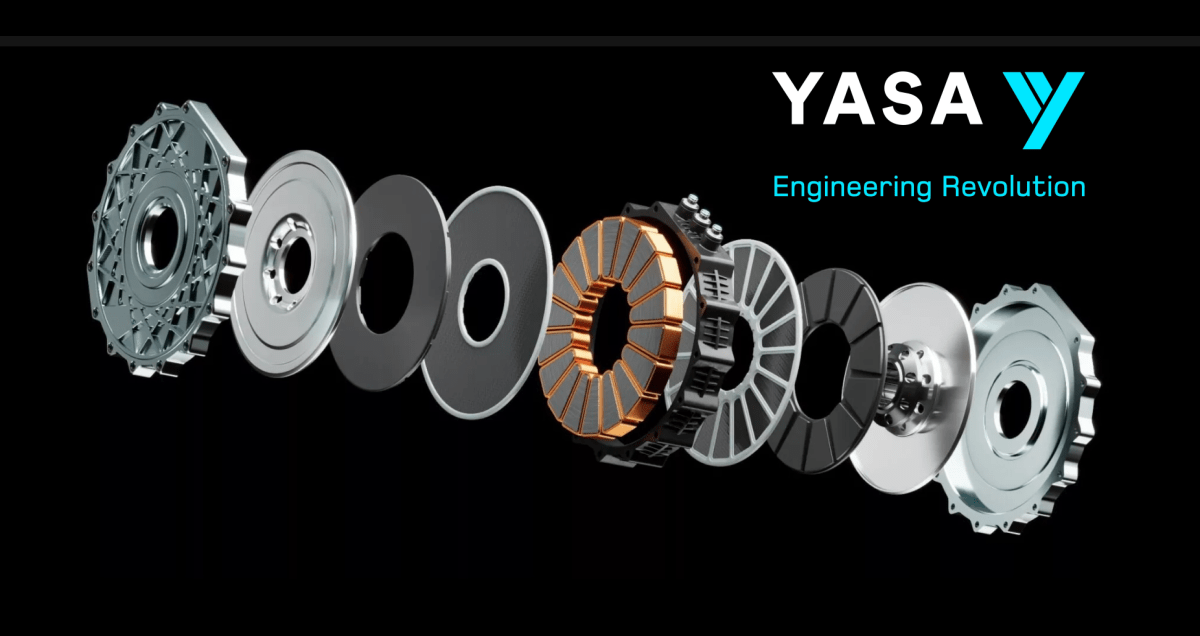

For custom orders, our technical application engineering team gets involved. The TFC Technical Team work with your engineering department to understand the requirements, specify appropriate materials and outline the specifications. We prototype and design your parts, and once agreed upon, the technical team relays the design via CAD drawings to Smalley to complete the order.

Our technical team offers the same technical design support for the ARaymond Quick Connectors.

CAD Models

Standard ring and wave spring models are available for download in all major CAD formats. We can also help you design bespoke retaining rings and wave springs specific to your application and have the design ready for production in CAD format. This service is ideal for clients looking to have the rings designed and submitted for manufacturing. Contact our engineering department for more details

Optimised Design

Our engineers work with you, using the criteria you select, to determine the design alternatives that will best suit the application.

From experience, we know the best engineering work isn’t always the most complicated. Simple adjustments like material thickness, radial wall, and number of waves, or making the ring or wave spring from a different material, can have a huge positive impact on the project’s success.

With our technology and software, you can save time and ensure the correct parts are manufactured and ready for prototyping and testing.

Prototyping & Testing

Prototyping the design to allow for initial testing before bulk production is a crucial part of the engineering process. It’s just as vital as the designing phase and requires the materials and expertise to get the right results, which determine whether you have the right product or if a redesign is necessary.

We offer factory testing on our products to ensure they satisfy the stringent industry standards and any additional standards required for your project before shipping.

We conduct Statistical Process Control (SPC) through randomised sampling of parts to verify that critical dimensions are within the required tolerances. We can also test various application-specific performance characteristics to instil confidence in our clients in the rings and springs they purchase from us and their ability to flourish in their applications.

An example of the other types of testing we can conduct includes ascertaining the cycle life of a spring or a ring product.

Re-engineering

Some clients might use our Spirolox Retaining Rings or Smalley Wave Springs to replace an existing product. Our engineering department can help you choose the best products for your applications and, more importantly, find the best design for your application.

With as little as a sample of an existing ring or spring and drawings of the assembly or your design requirements, we can engineer and provide you with new solutions for your consideration.

After providing you with an alternative design, we can work with you to obtain the exact prototypes or samples of similar products for evaluation and testing.

We can also achieve mid-stream design changes with relative ease. It is not uncommon for dimensions to need modification in the middle of production. Smalley products can be adjusted at any point in the process by making machine adjustments without any tooling changes.

The flexibility of our Smalley products ensures you have perfect-fitting products for all your applications and functions. Contact our engineering department for more details

Innovation for Over a Century

Smalley has evolved to become a world leader in the production and development of Spirolox® spiral retaining rings, snap rings and wave springs.

Smalley’s product line consists of 10,000 standard carbon and stainless steel parts, as well as custom design solutions in exotic alloys or customer-specific dimensions. All Smalley standard parts are manufactured using RoHS and REACH compliant raw materials and anti-corrosion agents.

When time is of the essence, Smalley’s No-Tooling-Cost™ manufacturing process allows for rapid prototyping and cost-effective production. TFC engineers are available for design consultation, providing customers with a full range of resources to ensure their application includes the most cost-effective and appropriate solution possible.