Vendor Managed Inventory (VMI)

Delivering the C-Parts your manufacturing process requires exactly when they’re needed, through a streamlined and efficient system.

What is Vendor Managed Inventory?

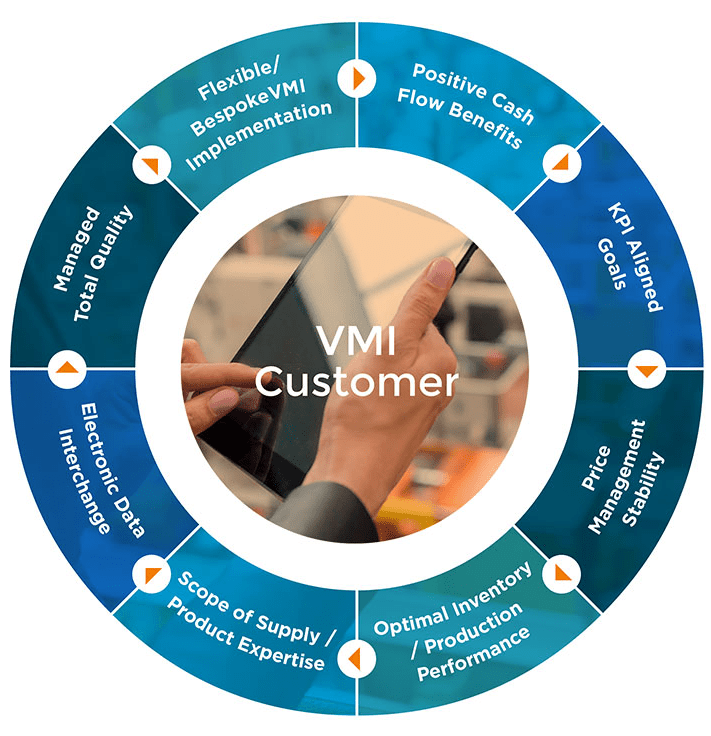

TFC’s Vendor Managed Inventory (VMI) provides a streamlined system tailored to significantly improve production performance, managing C-Part inventory in your business to your business.

Our customers experience on-time material supply, smarter stockholding and local support to bring about positive cash flow benefits, ongoing logistical expertise, and a can-do approach to their biggest challenges.

Sometimes referred to as;

- Direct Line Feed (DLF)

- Just In Time (JIT)

- KanBan

TFC has recognised that a “one-size-fits-all” approach is not the answer. We design our solutions to offer a flexible VMI system that caters to your specific requirements captured during a comprehensive site survey.

Through a close relationship with our local teams, TFC’s global reach means we can support your product and supply chain needs wherever they are in the world.

TFC’s approach to vendor managed inventory is like the service itself: simple and removes the work from your team.

Typical engagements follow this approach:

Easy Steps to Implementaion

1. Get In touch

2. Our experts will assess your requirements, usually through an onsite survey covering:

- Do you have a current incumbent system?

- Inventory requirements

- Monthly parts usage

- Any specialist requirements

- Future roadmap and associated changes

3. Sample approval process (if required)

4. We’ll present the most suitable options and competitive pricing.

5. We then engage the delivery team and seamlessly install your bespoke VMI solution.

6. Go live

1. Get In touch

2. Our experts will assess your requirements, usually through an onsite survey covering:

- Do you have a current incumbent system?

- Inventory requirements

- Monthly parts usage

- Any specialist requirements

- Future roadmap and associated changes

3. Sample approval process (if required)

4. We’ll present the most suitable options and competitive pricing.

5. We then engage the delivery team and seamlessly install your bespoke VMI solution.

6. Go live

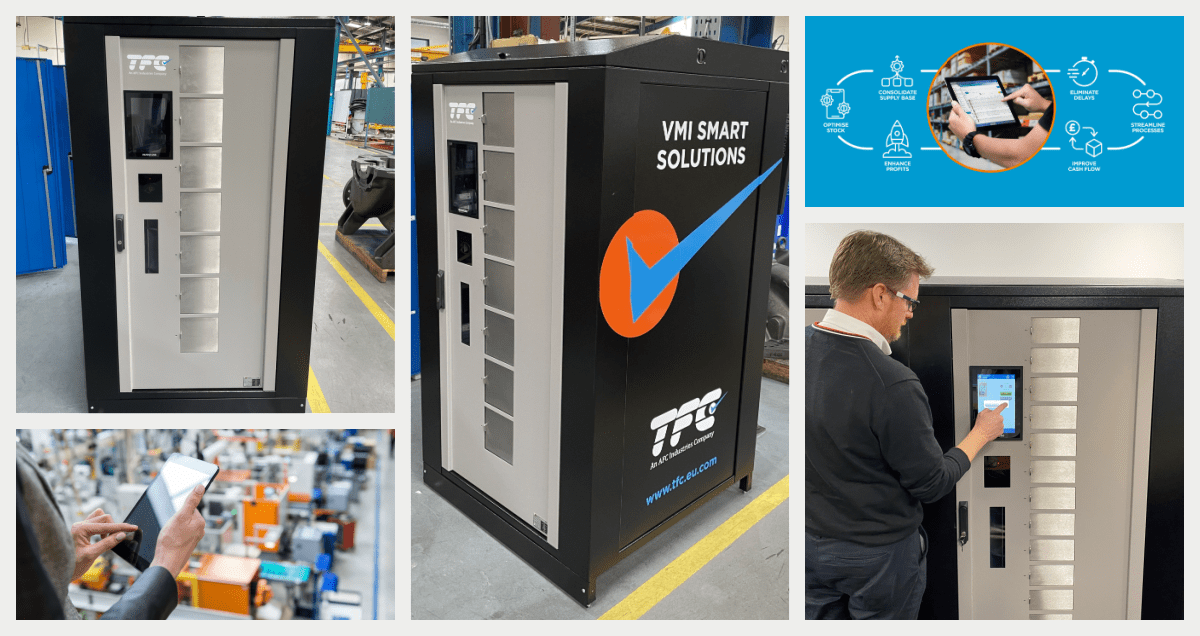

Industrial Vending Machines

Inventory and tool management are crucial areas for companies aiming to reduce losses. Industrial vending machines are an ideal solution to minimise inventory loss, equipment shortages, and theft.

These machines function similarly to those found in supermarkets and airport terminals, but with enhanced security and control features to prevent inventory loss. They dispense only the necessary parts and equipment, helping companies manage their inventory efficiently by maintaining only what is required for daily operations.

Industrial vending machines effectively bridge the gap between material and component demand and their delivery to the right personnel and processes, thereby increasing operational efficiency and reducing losses.

Typically, businesses need to source the industrial vending machine from one supplier and the software from another. However, TFC offers a comprehensive solution by providing the machine, software, and services all under one roof. This integrated approach not only simplifies the procurement process but also enhances the overall customer experience.

Advantages of Our Vending Machine Services for Industrial Supplies

Industrial vending machines offer significant benefits to industrial processes compared to traditional inventory methods. Key advantages of implementing an industrial vending programme include:

Shrinkage control

Industrial vending machines enhance accountability at all levels of production. They improve the monitoring of high-value tools and components at the employee level, with set limits on the quantities of items released to prevent over-usage. This enhances control of tool circulation, while monitoring usage and preventing leakage and theft.

Safe storage of chemicals

Many industrial processes involve chemicals, which can pose significant health risks to employees without proper storage. Industrial vending machines can be configured to store hazardous chemicals in locked, controlled-access cabinets. These cabinets can be programmed to allow access only to authorised personnel, ensuring safe and secure handling of sensitive materials.

Easy monitoring and reduced consumption

Operations managers can effectively monitor and control the circulation of tools and components, as well as manage consumable and expendable items.

Most industrial vending machines come equipped with real-time inventory analysis software, providing an accurate picture of expendable items, tools, and gauges used daily, weekly, monthly, or quarterly. This advanced monitoring capability helps reduce consumption and optimise inventory management.

Health & Safety

Ensuring the right Personal Protective Equipment (PPE) is readily available is crucial. For example, an employee welding will need different gloves than someone handling toxic liquids.

Industrial vending machines can identify the individual requesting PPE and dispense the specific equipment needed. This capability reduces the risk of lawsuits, as real-time tracking and access control allow Health & Safety teams to know exactly what PPE was taken by each employee. Additionally, it ensures that the necessary PPE is always available.

Other advantages of having an industrial vending machine are:

- Prevent stock-outs

- Limit obsolete items

- Optimising inventory storage footprint

Components of an Industrial Vending Machine

We deliver industrial vending machines as a complete unit, comprising various components that work together to provide the benefits mentioned above.

The cabinet

Our industrial vending machines feature hermetically sealed, triple-layered, multi-door cabinets to ensure the highest level of security. These cabinets can be customised to suit the client’s specific application and requirements.

For environments where contamination control is critical, the cabinets can be designed for positive pressure ventilation. This system uses natural convection currents to maintain a negative pressure atmosphere inside the cabinet compared to the outside, reducing contamination. Positive pressure ventilated cabinets are ideal for industries such as cleanrooms, laboratories, medical device manufacturing, electronics manufacturing (e.g., semiconductors), and aerospace/defence, where protection from airborne contaminants, dust, or other particulates is essential.

The safety system

Our unique and innovative safety system is integrated into the cabinet, ensuring only authorised personnel can access it. Access is restricted through biometric authentication or RFID cards, preventing theft and unauthorised usage of valuable equipment and supplies.

The dispensing system

The machines feature an auto-dispensing system that allows for the release of single items only, ensuring accountability and reducing the risk of unauthorised access. This system can be adjusted based on client requirements and specific applications. The semi-auto function ensures each item is counted, providing added security and control.

How do Industrial Inventory Control Vending Machines Work?

The machine is stocked with tools, consumable items, or components necessary for the current process. Employees are more likely to be accountable for their tool and supply usage when they know it is being tracked, leading to more responsible usage and preventing misuse or neglect of equipment. The machine can be accessed by authorised personnel in several ways.

Users can select the required tool from a touchscreen mounted on the front of the machine and provide a machine-readable identification tag. Other access methods include scanning a barcode on an employee tag, using biometrics, or proximity and smart cards. Once the user is confirmed, the machine dispenses the necessary tool or component in a few seconds and logs the request details. When the item is returned, the machine updates its inventory accordingly.

Software for Industrial Vending Machines

TFC provides both the vending machine hardware and the inventory management tracking software, ensuring seamless delivery and customisation to match your specific needs and applications.

The software tracks parts and supplies easily, allowing management to create transaction and inventory reports effortlessly. It can track orders by customer or work order, ensuring the right parts are delivered at the right time. The software delivers real-time stock and sales reports, saves time in money management, and tracks inventory throughout the business.

What Industries Benefit from Industrial Vending Solutions

Industrial vending machines have a wide range of applications, primarily leveraged in the following industries:

- Construction

- Aerospace

- Automotive and Transportation

- Manufacturing and machining

- Utilities

- Government and military

These machines can dispense various industrial tools and components, such as:

- Medical tools and supplies

- Precision tools and gauges

- Communication devices

- Work tools like screwdrivers, drill saws, and wrenches

- Personal protective gear (PPE)

- Machine calibration equipment and gauges

- Computer components like keyboards and mice

Industrial vending machines are a win-win solution for companies of all sizes, requiring minimal maintenance, incurring low costs, and providing numerous benefits. With TFC, you also receive servicing for the machine, ensuring worry-free maintenance.

With comprehensive, customisable, and quality solutions, TFC provides everything you need in an industrial vending machine. We have the experience and technology to deliver effective and convenient industrial vending machines that make a real difference in your business.

TFC can deliver our VMI service in highly automated, smart vending machines suitable for enterprise-level and security-conscious customers. Providing digital, cloud-based inventory counts and access management based on individual roles.

TFC’s customisable portfolio of Smart Solutions combines one of the most flexible inventory management systems available with industry-leading intelligence software to improve your control, leakage, security, compliance, and availability.

Smart Vending Solutions

Peace of mind that high-value inventory is secure and controlled

Reduction in the unnecessary turnover of inventory

Improved forecasting and demand schedules, linked to TFC branches to oversee stocking

Improved compliance for H&S

What Our Customers Have To Say

- TFC’s service had unlocked so much potential in their business

- He was no longer buried in resource investment and time-consuming distractions.

- He was now able to focus on the essential issues in their business:

Unlock the Potential of your Manufacturing - and your Purchasing Team

TFC’s Vendor Managed Inventory (VMI) solutions offer significant advantages for managing C-parts in manufacturing:

- Availability Assurance: VMI ensures timely availability of necessary parts, preventing production delays due to stock-outs.

- Cost Savings: Smaller, more frequent orders reduce inventory costs, while the supplier’s expertise optimises stock levels.

- Efficient Turnover: Our VMI improves inventory turnover rates, minimising excess stock and carrying costs.

- Reduced Admin Burden: Let TFC handle ordering and replenishment, all behind the scenes, freeing up your team’s time to innovate more and increase efficiency. No need for issuing multiple POs and paying multiple invoices each month.

- Consolidation & Stable Supply Chain: Collaborate closely with just one supplier and let TFC manage the multiple, disparate suppliers for a stable, efficient supply chain

What’s included in TFC’s Vendor Managed Inventory solution?

We are the masters of C-parts sourcing – You name the part, and we’ll source it.

Whether it’s a simple threaded bolt or a complex bespoke product made to customer drawing specifications, our quality-assured fasteners are guaranteed to provide the perfect solution to your fastening needs.

From bolts to rivets, seals to pipe fasteners, and everything in-between and beyond.

Enabling manufacturing beyond fasteners and managing the supply chain so that you can focus on your business.