Description

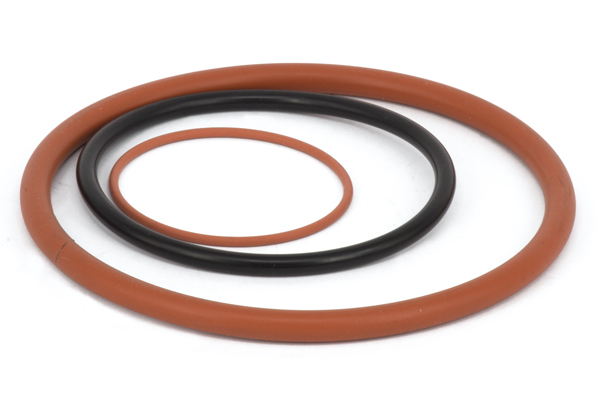

Our O-Rings and Seals Division carries an extensive range of over 30 million O-Rings in the most common materials:

- Nitrile (Buna / NBR)

- Fluoroelastomer (FPM / FKM / Fluorocarbon / Viton®)

- Silicone (VMQ)

- Fluorosilicone (FVMQ)

- EPDM

- Chloroprene / Neoprene®

- PTFE

- Polyurethane (PU)

- PTFE Encapsulated Silicone and Viton® (FEP)

In addition to our extensive range, we also supply High Nitrile, HNBR, Aflas®, Butyl, Natural Rubber, Hypalon, and many others, available in a range of colours and Shore Hardnesses. For more demanding situations, we offer a range of Perfluoroelastomers / FFKMs, including Kalrez®, Chemraz®, Isolast®, and Perlast®. We can provide fully molded non-standard O-Rings up to 700mm ID with a full range of cross-sections in many materials, hardnesses, and colours without tooling costs and with tight lead times. We also offer Scarf Jointed and Vulcanised rings for static applications with non-standard sizes as cost-effective alternatives to molded rings.

Did You Know?

Niels Anton Christensen (16 August 1865 – 5 October 1952) was a Danish-American inventor whose principal invention was the O-Ring, the ubiquitous hydraulic seal. In 1933, from his basement, Christensen discovered through trial and error that a ring-shaped piece of rubber in a groove made a reliable seal for a piston sliding in a cylinder. He applied for a patent, which was granted approximately two years later.