Description

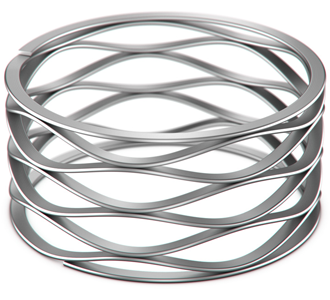

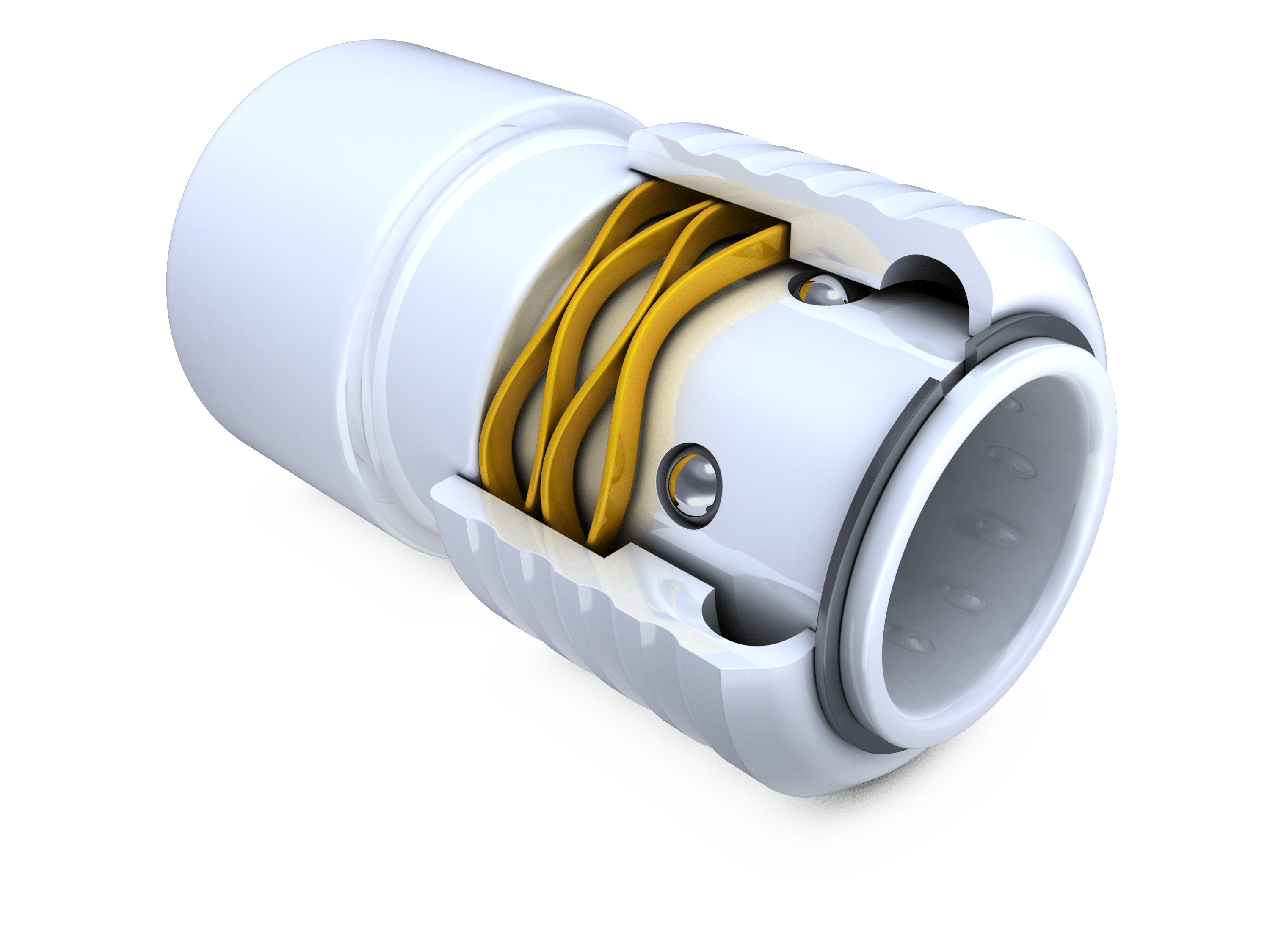

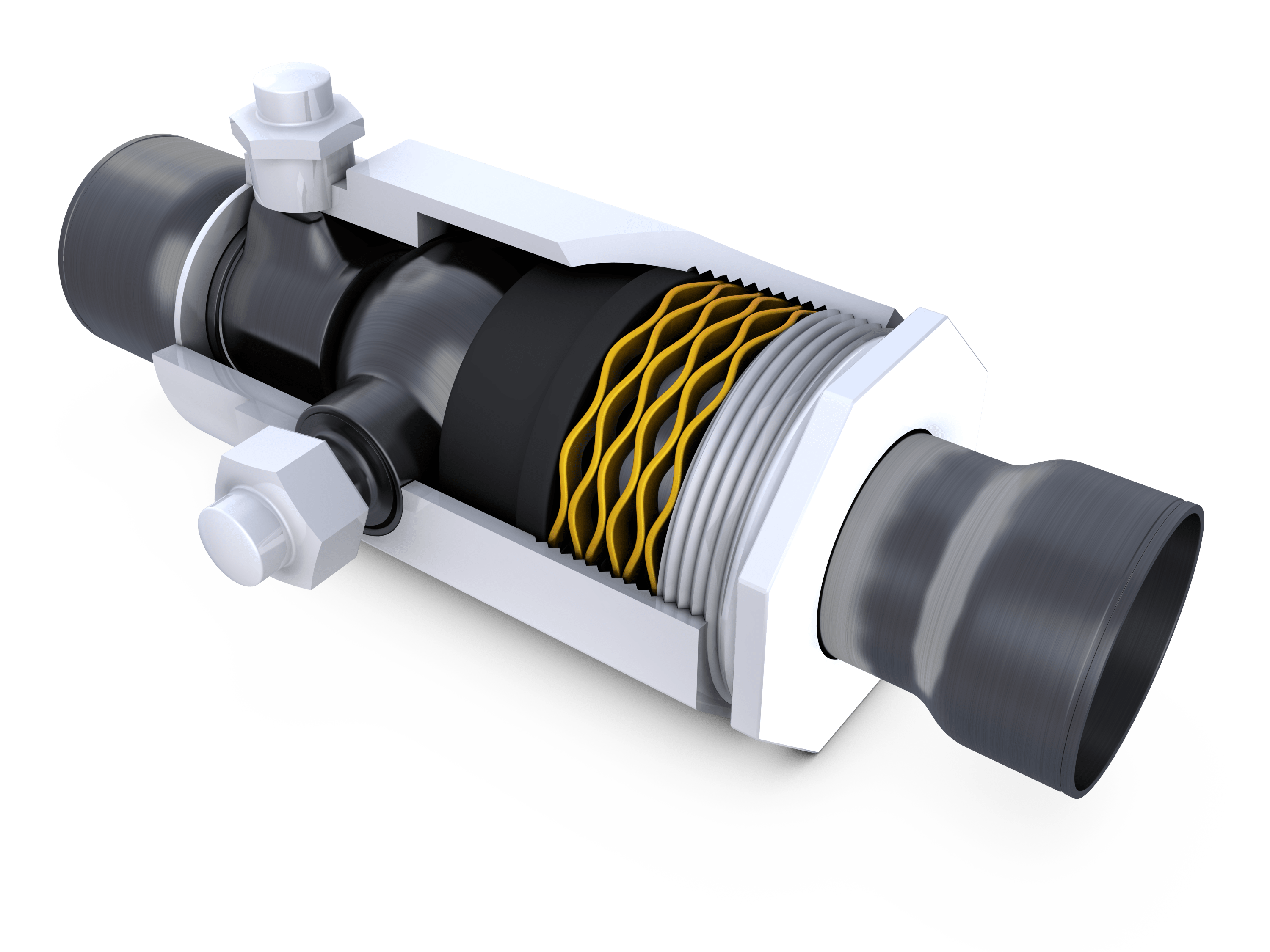

One of the main advantages of the Crest-To-Crest spring design is the elimination of the need to keep wave crests in a single line. There is no requirement for a key seating mechanism or inserting shims between individual springs. Because the spring is integrally formed, the wave peaks maintain their positions.

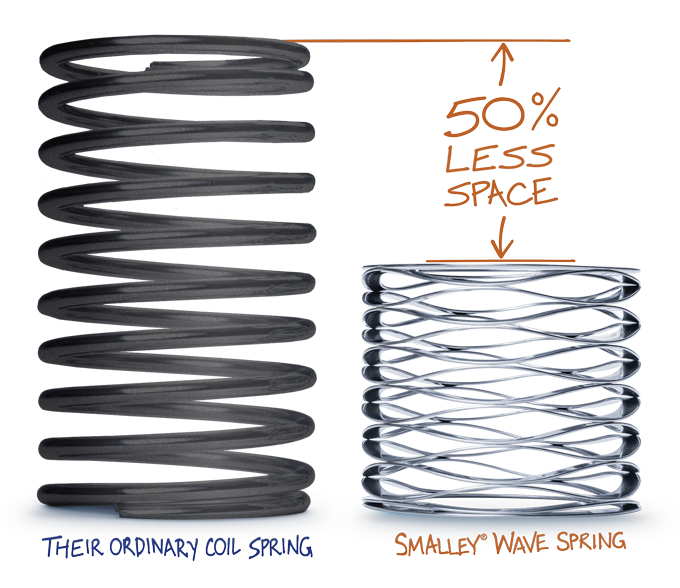

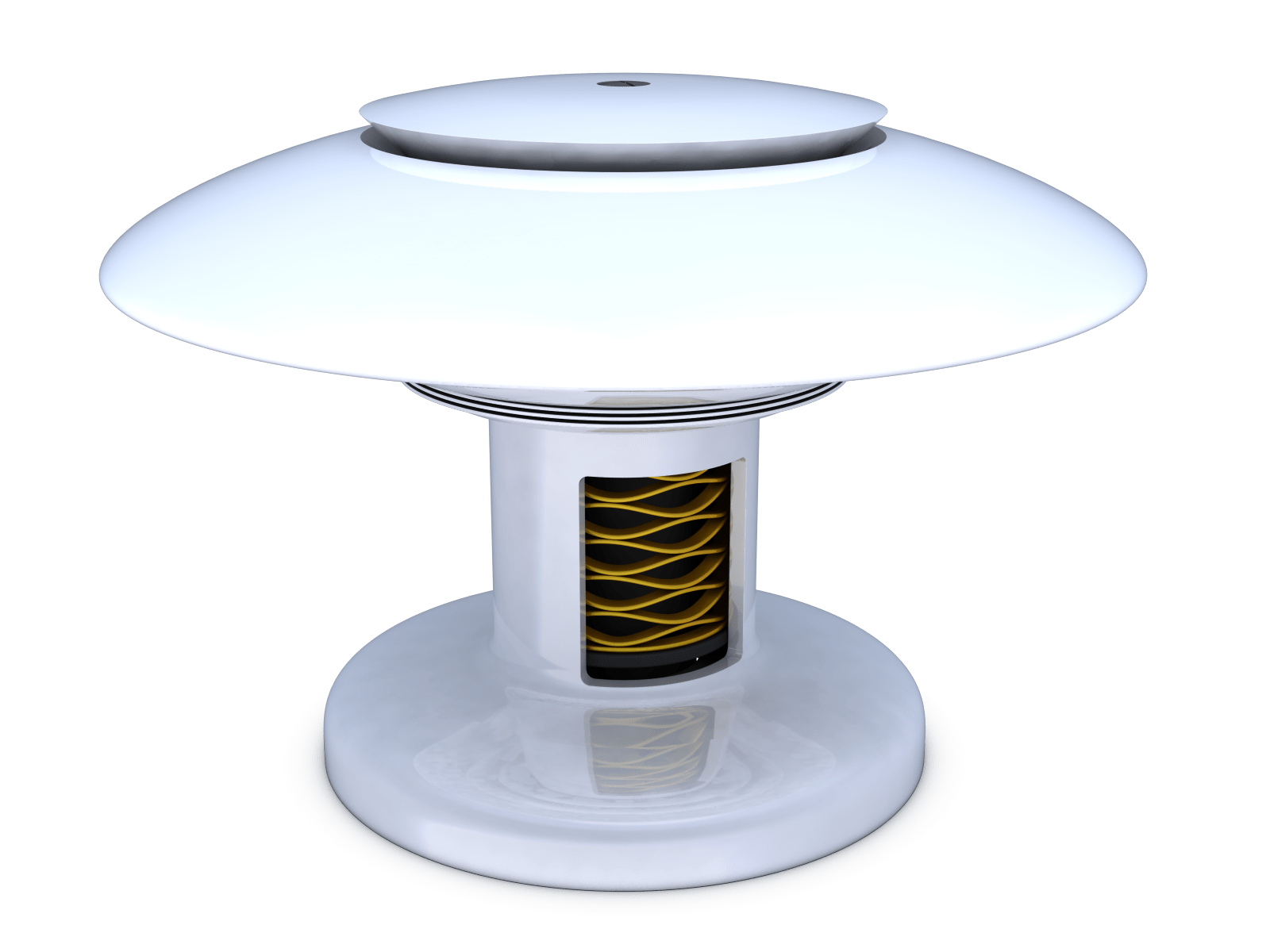

As an alternative to helical compression springs, Crest-to-Crest springs can generate similar forces but occupy half (50%) or less of the axial space. This allows for tight space constraints. These springs maintain the same force and load specifications as round wire springs but with the benefits of reduced and compacted working heights, free heights, and solid heights.

Materials: Carbon steel and stainless steel 17-7 PH/C. Alternative materials available upon request.

YCM Series: without a flat end, available standard sizes from 5 mm to 60 mm (please contact a TFC engineer regarding the 5 mm size).

YCMS Series: with a flat end, available standard sizes from 8 mm to 60 mm.