~Elevate your e-Bike performance with Smalley technology~

According to data from the Bicycle Association, 165,000 electric bikes were purchased in the UK in 2022, meaning the UK remains a less mature market than Germany, where two million are sold yearly. However, representatives at the 2023 Cycle Show in London agree that the market is gaining momentum after a bumpy few years. Growing the e-bike market requires manufacturers to effectively design appealing products, manufacture them efficiently and scale up e-bike production profitably. Here Simon Ward, technical manager at TFC, an AFC Industries company, explains why e-bike manufacturers are turning to components manufactured by edgewinding to solve e-bike design challenges. On the future of e-bikes in the UK, the Bicycle Association’s executive director Steve Garidis said: “It’s clear looking at the sales data — particularly comparing the UK with European countries like Germany and France — that we risk being left behind here. However, e-bikes clearly have huge potential, which could be unlocked here in the UK.”

Smalley: Maximising E-Bike Performance with Wave Springs and Retaining Rings. Space-saving. Lightweight. Optimal Kinematics

E-bike Manufacturing Trends

In e-bikes, springs and retaining rings can be used in drive technology, wheel hubs, braking systems, as well as throughout the structural framework. Wave springs solve design and manufacturing problems by compensating for tolerances and preloading bearings for optimal performance. Spirolox® retaining rings provide 360° retention across multiple internal and external applications, whilst Hoopsters are particularly well suited to tubular frames due to the shallow groove requirements.

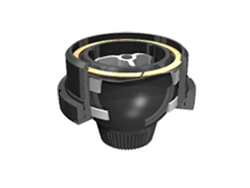

Enable space-optimised designs: Smalley’s Spirolox® circlips

In recent years, design engineers have moved away from stamped springs and retaining rings and towards ones made via edgewinding. This method involves coiling wire on edge to create springs or retaining rings to precise specifications. The process gives more flexibility to manufacturers in terms of bespoke sizing and allows wider material choices to be considered.

In addition, the circular grain metallurgy increases the strength and stability of the material — cold rolling causes metal grains to elongate and lock together, which improves mechanical properties. Since the grain follows the direction of the coil, it provides better mechanical properties than if it were to be stamped from sheet material where grain flow is in just one direction.

Wave Springs in E-bike Design

One example of a component made by edgewinding is a Crest to Crest® wave spring, an alternative to the traditional coil spring. Crest to Crest Wave springs are flat-wire compression springs offering the same spring force as a conventional wire round spring but at 50 per cent of the operating height.

Single-turn wave springs are perfect for preloading bearings, while for applications with higher forces, designers may prefer nested wave springs composed of multiple layers nested together to provide a compact high-force solution.

Fixing a sprocket in position with a two-layer wave spring from Smalley

Retaining Rings

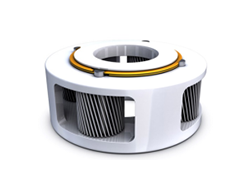

In e-bike drivetrain technology, retaining rings are used for securing bearings on shafts, as retaining elements in gear assemblies. Here too, designers are opting of flat-wire spirals due to their improved performance. Compared with traditional stamped circlips (DIN 471/472), they have no protruding lugs and, depending on the variant, no gap in the circumference.

Achieving Superior Sealing: Smalley’s Double-Layered Ring for Planetary Gears

Even in situations with limited radial space or where rotating components require minimal imbalance, flat wire retaining rings are the preferred choice of many e-bike designers.

The edgewinding process creates components with many technical benefits. From space-saving to easy installation, wave springs and retaining rings can help UK e-bike manufacturers produce appealing products to support this growing industry.