Find out how to improve your C-Part procurement efficiency today.

This comprehensive guide is your toolbox for improving procurement efficiency and preventing disruption on the production line. From understanding the significance of C-parts to mastering procurement, this guide is your go-to resource for creating more efficient, productive, and cost-effective procurement.

Click the button below to download your copy of:2025 Vision: The State of C-Parts Procurement and Supply Chain Management

Table of Contents

Production lines rely on effective procurement strategies to help keep businesses operating as usual. It is your responsibility as a procurement officer to do this. You are the person who buys the fuel for the engine to run. This takes the form of a steady supply of components that meet the required quality standards, ensuring timely deliveries and availability in the right quantities, all within budget.

Whilst high-value parts like A and B receive the most attention, the less visible, lower-cost C parts are equally important. Due to their lower cost, there might be more temptation to overlook these parts, but they are essential to the integrity and functionality of the final product. Overlooking the importance of C parts can lead to increased costs, excessive administrative burdens, and even production halts.

This guide will provide you with everything you need to know about C-parts—from understanding their significance to optimising their procurement—our speciality. As you explore our guide, you’ll encounter small tasks designed to enhance your understanding of C-part procurement in relation to your business operations. Whilst we encourage you to complete these tasks, simply reading the guide will still provide valuable insights.

What Exactly Are C-Parts?

Anyone in manufacturing knows that we typically categorise the hundreds of parts and components that go into a finished product into three clear categories: A, B, and C. C-parts are the lowest-value items, and you will also know their importance. Think of screws, nuts, bolts, pipes, O-rings, and other fasteners – the essential pieces that hold the final product together.

C-parts can either be standard in their design or high-tech, such as turned, injected, extruded, stamped, forged, milled, or moulded components. The cost of an individual bolt might be negligible and easily overlooked, but cost savings can still be found.

The variety of C-parts is enormous. In fact, C-parts make up 65-75% of all production line inventory. As a procurement officer, you will know more than most about the considerations for different fastener types, sizes, and capacities alone.

Importance of C-Parts in Manufacturing

We consider C-parts as critical to production as A and B parts. The quality of your C-parts directly impacts your products’ reliability and overall finish.

Often, their significance is only indeed recognised when something goes wrong. This guide serves as your proactive warning. Instead of experiencing the losses of poorly sourced C-parts firsthand, you can prevent such issues by following this guide and ensuring smooth operations.

Consequences of Poor Quality or Unreliable C-Parts

Downtime can be caused by machine breakdowns or human error, but parts shortages can also be a significant cause. Due to the large number of different C-parts with varying volumes, many companies need help to get a centralised overview of their availability over time. This problem can go unnoticed until it’s too late.

With fasteners, items can be assembled, and work can only continue once new parts are sourced. Procurement officers often bear the blame. Whether it’s unfair or not, unfortunately it happens, so you need a more secure system to prevent it.

Ensuring Availability of C-Parts

This is where vendor-managed inventory (VMI) expertise becomes invaluable for manufacturers with repetitive production cycles. By having a reliable system to manage the inventory of C-parts, companies can avoid the pitfalls of part shortages and ensure smooth, uninterrupted production. VMI allows suppliers to monitor inventory levels and automatically replenish stock as needed, reducing the burden on the manufacturer. This streamlines operations and minimises the risk of human error, leading to more efficient and cost-effective production processes.

VMI transforms the chaotic and error-prone tasks of manual inventory management into a seamless and reliable process. This enables manufacturers to focus on their core business activities without worrying about part shortages disrupting their operations.

The Paradox: Low Value but High Cost

So, if C parts are the lowest-value components used in a manufacturing option, it would lead you to presume that any financial fallout would be inconsequential. When buying in bulk, the price of an individual screw is nano. Yet, when we scratch below the surface, as someone who oversees incoming parts will have done, you soon learn that C-parts carry the highest indirect costs.

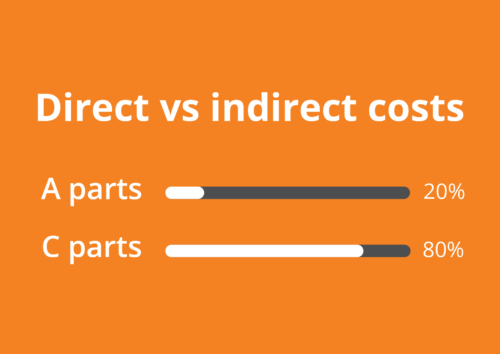

Typically, 80% of the total cost of C-parts is tied to sourcing, ordering, delivery, handling, and inventory management, leaving only 20% as direct costs. This is particularly striking compared to A-parts, where the situation is reversed.

Fortunately, reducing indirect costs is much easier than cutting down direct costs. Whilst you can negotiate with your supplier for better prices on higher-value A and B parts, you’ll find that there’s even more potential for savings by focusing on the indirect costs associated with your C-parts. Here are several procurement and supply chain management strategies you can consider to achieve this:

- Improve the order and delivery process.

- Increase parts availability.

- Consolidating suppliers,

- General improvement to your C-parts management.

As we’ve discussed, C-parts are small but essential. Not only do they keep the production line moving, but they also significantly impact the efficiency of inventory procurement. Companies often deal with hundreds of different C-parts; the average car comprises of over thirty thousand parts, which can mean managing hundreds of different suppliers. Smaller businesses face similar challenges; although they operate on a smaller scale, they still have to handle more suppliers than they would care to. Across the industry, numerous small orders must be received, processed, and paid for, leading to a substantial administrative burden. When you add up all this time, it becomes clear that the company is spending significant time and money on the seemingly simple task of purchasing essential parts.

The time spent sourcing parts, communicating with suppliers, and placing orders soon adds up, and time is a costly resource. You can see how associated indirect costs can become so expensive. The goal of any procurement officer is to get the best possible price for the goods they are buying – after all, money savings are what impresses the boss and makes you stand out – but since the direct cost of C-parts is low, minimal savings can be made through negotiating a price with the supplier. But savings can be made. The indirect cost is where you need to look at make reductions.

One fundamental way to do this is through supplier consolidation. Another is choosing a supplier with reliable delivery, smooth ordering systems, and lower lead times. This cuts the risk of downtime and all the associated costs. We have the perfect solution for you that does all of this.

C-Parts Procurement: An In-Depth Look

As the person in charge of procurement, you are crucial in supply chain management, particularly in sourcing components from multiple suppliers. Effective C-part supply chain management can be broken down into three key facets:

1. Planning

A strong and thorough plan is essential. It’s your responsibility to analyse and calculate the exact quantities needed to keep the production line running smoothly. Your performance might be judged negatively if your production line runs out of parts. However, at TFC, we understand that the situation isn’t always black and white. Sometimes, not having the right tools to create a coherent plan can be part of the problem. To maintain the right level of components, many companies overstock C-parts. Whilst this prevents downtime, it’s a costly strategy. Remember, strategic procurement and supply chain management should save the business money, not just shift expenses from one issue (downtime) to another (overstocking).

2. Sourcing

Sourcing is particularly pertinent to your role. Regardless of what your plant manufactures, it has many equally essential parts. Maintaining a consistent standard and supply of each component is non-negotiable. This is why selecting the right supplier is so critical.

If you are overwhelmed with managing the logistics of procurement, how can you possibly find time to improve processes? This is a classic case of “run vs. change”—being so busy with the day-to-day running of the business that there’s little time left for making improvements. Being stuck in the “run” phase is a reactive mode, primarily focusing on keeping everything running as smoothly as possible and putting out fires.

The reality is that often, you don’t realise you have procurement issues until it’s too late. It’s all good until it’s not. The floor staff and the manufacturers might not pay too much attention to the procurement team, which signifies a strong procurement system. However, if there are multiple suppliers’ failures, they will come to you for immediate solutions. Finding new suppliers becomes the most urgent task, with pressure coming from all directions – floor staff, managers and the C-suite.

When you master the “run” phase, you have more time to invest in the “change” phase. This involves stepping back, evaluating and improving processes to prevent disruptions. This could mean finding more reliable suppliers, negotiating better terms, implementing new technologies, or optimising inventory management.

Balancing “run” and “change” is essential for long-term success. Whilst it is crucial to keep daily operations running smoothly, dedicating time to strategic improvements can prevent future crises and enhance overall efficiency.

3. Organisation and Quality Assurance

Whilst you may not be involved in the physical manufacturing process, you are the bridge between quality craftsmanship and operational efficiency. When components arrive at your facility, you need an organisational process to ensure the correct part is in the right place when needed on the production line. This also involves quality assurance before committing to order placements, replenishment, and maintaining a constant supply of components.

Focusing on these three facets—planning, sourcing, and organisation—can ensure efficient and reliable C-part procurement and supply chain management, ultimately supporting the overall success of your manufacturing operations. Use this opportunity to reflect upon your existing plan, sourcing, organisation & quality assurance strategy.

- Do you have one in place? If so, how formal is it, and are procedures known and understood company-wide?

- When was the last time you reviewed and modified your strategies to keep up with industry challenges and trends?

- What are each’s strengths and weaknesses?

- Do you want something more than what the current infrastructure of your C-part procurement and supply chain management offers? What is that?

Current State of C-Parts Procurement and Supply Chain Management

In your role, you are pressured to tighten budgets and maximise profit and efficiency without compromising quality. Additionally, meeting manufacturing and specification requirements can be complex. These challenges can be broadly categorised into two umbrella terms: increasing inefficiency and threats to the company. As you read the key challenges below, consider which umbrella term they fall under.

Availability

If the C-parts you need aren’t available, production stops. C-parts must be consistently available in quantity, quality, size, and price at the right time. Long lead times, supplier issues, poor inventory procurement and supply chain management, and inaccurate forecasts are common problems. However, these issues won’t earn much sympathy if production stops due to a lack of essential components like nuts, bolts, or small-turned parts.

Ensuring availability largely depends on your choice of suppliers. The pandemic highlighted how disruptions can occur unexpectedly and affect supply chains globally. Therefore, having adaptable and proactive supply partners is crucial to ensure the best possible availability for your company.

Sourcing Suppliers

Bespoke parts are common in manufacturing, but sourcing these parts can be time-consuming. Many organisations have dozens or even hundreds of suppliers to manage, leading to significant administrative work for procurement officers and requiring collaboration with logistics and planning departments. This can be time-consuming and potentially an inefficient use of resources, despite proven solutions that can optimise this process.

Some companies seek suppliers overseas for cost benefits, which introduces complications such as language barriers, time zone differences, and lack of transparency, hindering proper sustainability audits. Additionally, issues like anti-dumping regulations in Europe and minimum order quantities (MOQs) from foreign suppliers make international trade more challenging. Refining your outsourcing and handling these operations more effectively allows you to focus on day-to-day activities.

Quality Assurance

Quality and specification assurance are vital. Compromising quality to save costs often leads to higher expenses in the long run. Poor quality or faulty C-parts can halt production lines, causing delays,jeopardising customer satisfaction and increasing costs. You may need to repurchase quality C-parts and pay employees to redo work. Even if poor-quality parts are usable, they can undermine the overall product quality, leading to returns, customer complaints, and damage to your company’s reputation.

Inventory Procurement and Supply Chain Management

A disconnect between purchasing and manufacturing often stems from inventory-related issues. As a procurement officer, you need a clear picture of current C-parts in stock, usage rates, and forecasted usage to maintain reasonable stock levels. Establishing clear communication lines with manufacturing procurement and supply chain management is essential to stay updated on shortages and upcoming requirements.

It can be exhausting to be solely responsible for ensuring the availability and quality of parts, constantly monitoring inventory levels, and dealing with suppliers. It would be useful to delegate these tasks and achieve guaranteed results. That’s where VMI comes in.

Solutions for Addressing Pain Points in C-Parts Procurement

As with many problems in various aspects of life, digitalisation is fast becoming a solution in some capacity. This is true here as well. Here are some modernisations and alternative approaches to procurement you should consider as you head into 2025.

Technology Integration

Role of digital tools and platforms in improving C-Parts procurement:

Automated ordering systems streamline the procurement process by automatically placing orders based on predefined criteria, reducing manual intervention and errors. Automation can help you simplify processes during procurement, from supplier & contract management, to sourcing and purchase order processing.

Real-Time Inventory Tracking:

This allows for accurate monitoring of stock levels, ensuring timely replenishment and minimising stockouts or overstock situations. This helps businesses stay within budgets and see potential for savings. It can also help businesses predict problems and proactively respond before they cause disruptions.

Data Analytics:

Leveraging data analytics helps make informed decisions by analysing procurement patterns, supplier performance, and cost trends, leading to more strategic procurement practices.

Supplier Consolidation

The benefits of working with fewer, more reliable suppliers

By consolidating suppliers, the procurement process becomes more straightforward and manageable, reducing administrative burden and potential errors. An added benefit of fewer suppliers means stronger relationships and better communication, leading to more efficient and effective procurement operations. Increased volume and loyalty can also result in better pricing and terms.

Vendor Managed Inventory (VMI) Solutions

Many companies have found significant benefits in using vendor-managed inventory (VMI) supported by an effective logistics solution. In such a C-parts procurement and supply chain management system, the supplier takes responsibility for organising and optimising the inventory. In some cases, orders for new parts are automatically placed when stock levels fall below a certain threshold, further reducing your workload. These solutions can significantly alleviate inventory-related issues and help prevent downtime and stock shortages. As part of the VMI service – TFC maintains stock and automatically reloads the bins as stock levels fall, with the added benefit of the customer not paying for stock until delivered to the site. We make sure you have warehouse stock ready for when the workshop floor needs it.

Rest assured, a vendor-managed inventory (VMI) system is not designed to replace you, but to make your job easier. It allows you to redirect the time previously spent chasing suppliers to more productive tasks that will help you stand out to your boss. At TFC, the role of a procurement officer is not to constantly put out fires, but to create an environment where no fires need to be put out. Instead, you can focus on optimising and improving day-to-day operations.

What is Vendor Managed Inventory (VMI)

A vendor-managed inventory is where a third-party provider is responsible for sourcing components and managing the supply and flow of parts to the factory floor. The VMI partner ensures that parts, fixings, consumables, materials, and other products are delivered precisely where and when needed, providing timely stock replenishment according to a predefined delivery schedule. Consequently, the customer avoids any disruptions in manufacturing due to the unavailability of specific C-part products. This approach is especially beneficial in the current climate, where sourcing stock can be challenging, and businesses need longer lead times.

Why Vendor Managed Inventory (VMI) Holds More Potential than Traditional Inventory Procurement

In C-part procurement, Vendor Managed Inventory (VMI) stands out as a highly effective solution compared to traditional inventory procurement and supply chain management methods because of its ease and efficiency. Here’s why you should consider it:

- Streamlined supply chain

- Improved availability

- Cost efficiency

- Enhanced supplier relationships

- Better forecasting and planning

- Reduced risk of human error

- Adaptability to disruptions

Vendor-managed inventory (VMI) addresses the challenges of traditional inventory procurement, offering a superior approach for effectively managing C-part procurement. Interested in how VMI solutions can achieve this? Speak to a member of our TFC team today.

VMI in action…

Customer Challenge

TFC Solution

What TFC can offer you:

- A system that makes your supply chain work for you.

- Streamlined internal processes and administration.

- Material availability to enable capacity growth.

- Consolidatation of your supplier base,

- Smart stock procurement and supply chain management and control.

- Access to a proven, high-quality global supply chain.

- A partner to create continuous value.

TFC Smart Solutions

Security & Control: Have peace of mind knowing that high-value inventory is secure and tightly controlled. Our systems provide real-time visibility, reducing the risk of loss or mismanagement.

Reduced Turnover: Avoid spending on stock. Our solutions optimise stock levels, preventing overstocking and shortages.

Enhanced Forecasting: Linked directly to TFC branches, our systems improve demand schedules. Accurate forecasting means better resource allocation.

Compliance & Safety: We take compliance seriously. Our solutions ensure adherence to health and safety regulations, protecting your workforce and business.

But that’s not all. Our solutions take efficiency to the next level. Imagine having the right item in the right place, at the right time – every time. Prevent work stoppages, control costs, and boost productivity.

Conclusion

Whether you stumbled upon this piece or were actively seeking a solution, we hope you have gained valuable insights into improving C-part procurement efficiency. You are not alone in feeling the pressures and challenges of C-part procurement, but failing to address what isn’t working could leave you behind your competitors.

Building an inventory procurement and supply chain management solution is complex, but with the proper support, integrating automated technology can simplify product availability, even in unpredictable manufacturing environments.

Explore TFC’s VMI solutions to upgrade your C-Parts procurement and supply chain management, or contact a member of our team for assistance in implementing the right mix of digital technology into your business.