Enabling Supply Chain Excellence Our Bespoke Vendor Managed Inventory Services

TFC VMI solutions simplify your supply chain, facilitate capacity growth, streamline business processes, and enhance profitability. Working with TFC, the UK’s fastest-growing Vendor Managed Inventory (VMI) solutions provider, means placing your trust in the best possible hands.

With many clients in the UK and worldwide, TFC has helped companies achieve significant benefits associated with implementing an approved, high-performing VMI system combined with the purchasing, stock holding and handling of a wide range of products and components.

Whether referred to as Direct Line Feed (DLF), Just In Time (JIT) or KanBan, our VMI has recognised that a “one-size-fits-all” approach is not the answer. We design our solutions to offer a flexible VMI system that caters to your specific requirements captured during a comprehensive site survey.

With the personal relationship of a local supplier, our global reach means we can support customers’ products and supply chain needs wherever they are in the world.

Working with your technical and quality teams, we can operate behind the scenes advising more effective components and fastening solutions to bring the benefits of product rationalisation and optimal material selection.

Our reputation has been built, above all, on the quality of our products and the level of technical and logistic services. Our mission is to provide an outstanding contribution to our customer’s success by supplying innovative products and services in all areas where we can add value and help our customers improve their business. Whether it is a simple threaded bolt or a complex bespoke product made to customer drawing specifications, our quality assured fasteners are guaranteed to provide the perfect solution to your fastening needs.

- Bolts & Socket Screws in various grades

- Nuts, Washers, Rivets & Screws of all types

- Circlips, Springs, Keys and Seals

- Threaded Inserts – for plastics, timber & metal

- Electronic Hardware – standoffs, handles, ferrules

- Construction Fixings – anchors, through bolts, resin

- Panel, Wire & Pipe Fasteners

- Sheet Metal Fasteners – self-clinch & rivet bushes

- Bearings

- Seals and O-Rings

- Machined and turned parts to specification

- Tools, PPE & Consumables

With decades of experience, TFC is the leading European supplier of Smalley Spirolox Retaining Rings, Snap Rings and Wave Springs. Local stock availability and engineering design support from all TFC locations.

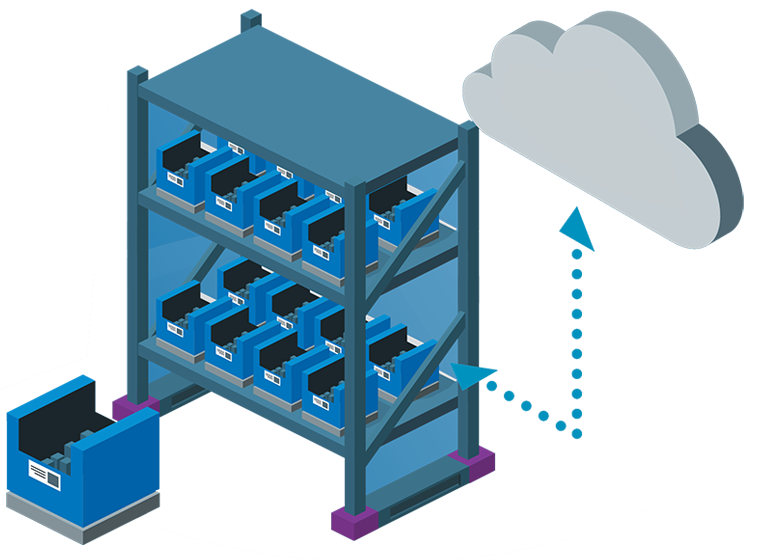

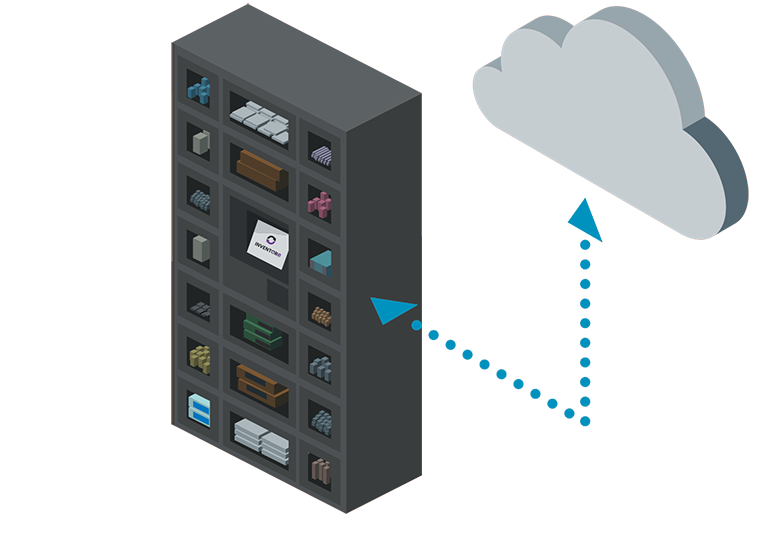

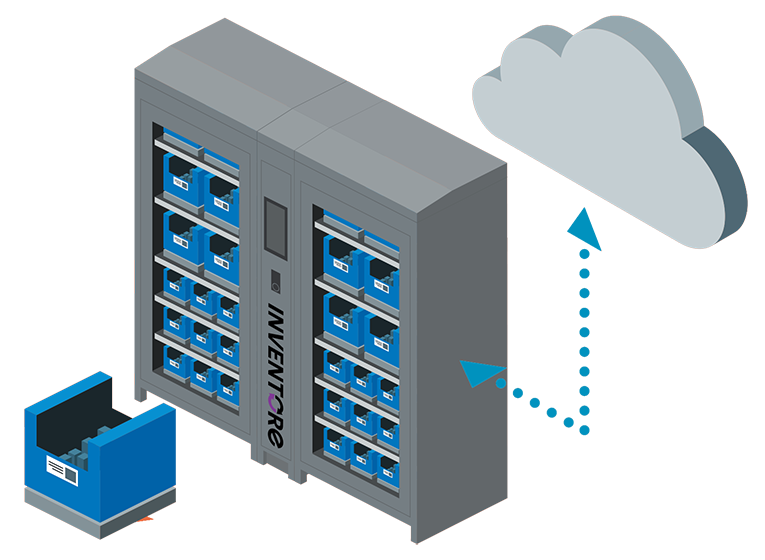

Vendor managed inventory (VMI) is a system where manufacturers outsource inventory management to a third party.

The third-party vendor takes full responsibility for the optimisation and management of the customer’s inventory. The vendor ensures that the right parts, fixings, consumables, material, and other products are delivered to the right locations at the right time, providing timely stock replenishment in-line with the predefined delivery schedule.

Look for a VMI partner that takes the time to understand your unique requirements, including material flow and the type and number of parts needed. A VMI system tailored to the exact requirements of your business will produce the best results.

When adopting a VMI system, remember that the service may need to evolve as the company grows. Choosing a VMI supplier that provides flexible VMI systems, good lines of communication, and access to a global market means that the partner can scale its service based on your needs, driving continuous improvement.

Vendor consolidation can significantly simplify inventory management. With TFC VMI, manufacturers will have a dedicated account manager, but will also benefit from the knowledge and expertise of a multi-disciplinary team.

TFC VMI allows manufacturers to:

- Streamline their supply chain through vendor rationalisation

- Continually monitor stock usage, allowing for adjustments as necessary

- Ensure continuity of supply, mitigating risk to the business

- Purchase parts for lower prices from the VMI provider due to its industry relations

- Reduce direct and indirect costs through process improvements and product standardisation

- Free up valuable warehouse & storage space & reallocate a workforce

- Manufacture quality assured products with full batch traceability knowing TFC have quality approved your requirements before supplying them

- Ensure end to end supply chain management

- Benefit from a VMI solution that is tailored to their specific needs

TFC’s logistical expertise is matched by its technical know-how. We can design a system to suit your specific needs, no matter the component, application or quantity. Whether you operate a track-line feed, direct-line feed or cellular manufacturing, we can arrange a bespoke stock replenishment system using the latest technology to ensure an efficient, continuous and worry-free supply of stock.

TFC’s logistical expertise is matched by its technical know-how. We can design a system to suit your specific needs, no matter the component, application or quantity. Whether you operate a track-line feed, direct-line feed or cellular manufacturing, we can arrange a bespoke stock replenishment system using the latest technology to ensure an efficient, continuous and worry-free supply of stock.

- The Group offer product expertise and technical design capability and we support stock rationalisation and standardisation reviews through our on-going review process or RFQ

- Our team give continuous support including regular business reviews and cost management proposals for

resourcing alternative supply options - Our Site Audit Surveys are undertaken by an experienced VMI advisor

- Our JIT solutions aim to reduce flow times within customer production systems and help control variation in processes, allowing an increase in productivity while lowering costs, similar to Lean production systems.

Fahr Industries Customer Testimonial

“We chose TFC for our VMI systems because they listened to our need and customised the solution accordingly.“

“From the start of the initial introduction, TFC stood out from the crowd with their enthusiasm, proven experience and knowledge.“

Case Studies: Our Work In Practice

Latest Vendor Managed Inventory Case Studies

Case Studies: Our Work In Practice

Latest Vendor Managed Inventory Case Studies

Latest Vendor Managed Inventory News

Follow us