Disc Springs, also known as Belleville Washers, are commonly used in high load engineering applications such as clutches and valves. In precision or safety critical products these basic springs may not offer the accurate loading or dimensional tolerances required of the application. Smalley’s range of Wave Springs offers a reliable and preferred spring choice for many engineers. Here are four good reasons why you should consider Wave Springs for your next project:

Quality

A common problem associated with disc springs and wavy washers occurs because of the differences in mechanical properties as a result of variances in production and heat treatment. All die-stamped products are manufactured from an annealed material that requires heat treatment after stamping and, because of the inconsistency in characteristics that results from this process, the load at defined working heights can vary enormously. A Smalley Wave Spring is produced by edge-coiling prehardened material to the correct diameter and wave height to produce a product with a guaranteed load at specified work heights.

Installation

Because of the reasons explained above, when installing disc springs, it is difficult to identify the correct number of springs/washers needed to achieve the desired load. In order to correctly understand the quantity needed, the engineer is required to ‘trial and error’ the assembly with a differing number of springs until the correct load characteristics are obtained. Apart from the obvious problem of time wasting, this also often results in trouble during production caused by the misalignment of the stacked components. In comparison, a single Smalley Wave Spring eliminates this guesswork as it is produced to the exact specifications for the application from a single coil of material and is ready for immediate installation when received by the customer.

No Tooling

Since Disc Springs and Wavy Washers are a stamped product, they require specific tooling to create the finished article whereas our Smalley products are produced by edge coiling and do not require any tooling. Furthermore, die-stamped products are produced from sheet metal and the waste products of this process, particularly where exotic materials such as Inconel and Elgiloy are concerned, is significant. The availability of Smalley products is almost instant since the wire is coiled in-house and is generally available off-the-shelf and can be produced to customer specific dimensions without compromise to the assembly.

Technical Design Support

TFC’s team of engineers are always on hand to assist in the design or specification of a spring to meet your application requirements.

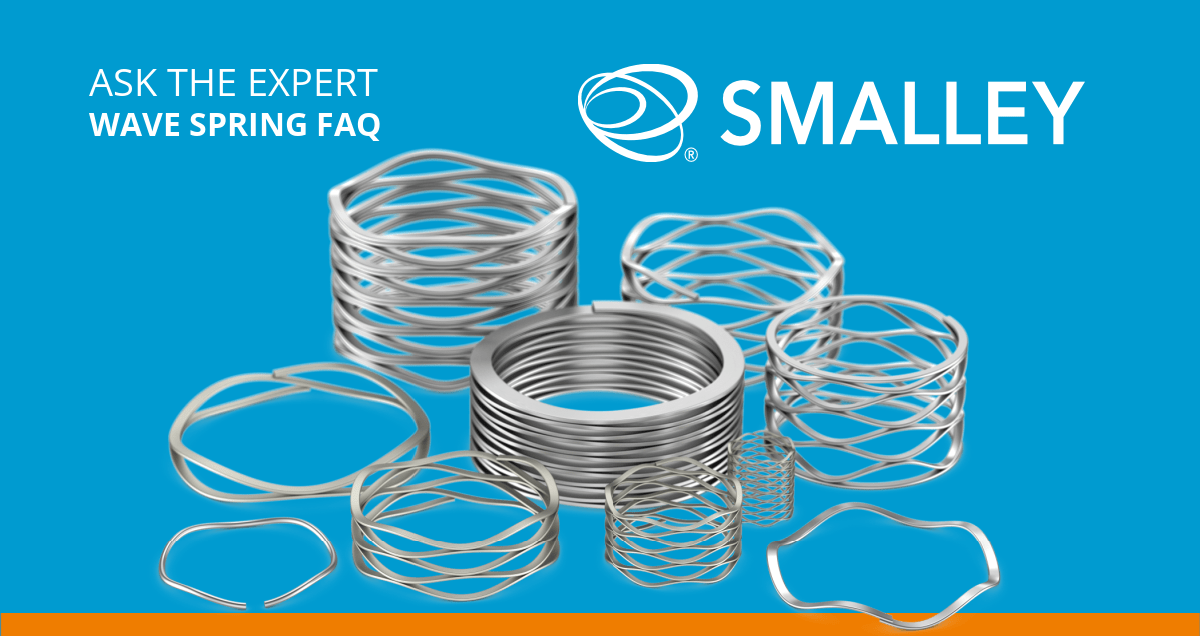

We are able to offer a variety of alternatives to Disc Springs and Wavy Washers. Our Smalley Crest-to Crest®, Nested, Interlaced and Wavo® Springs each offer an alternative solution and have been successfully specified in many high load engineering applications.

Standard product samples are always available for fit and function tests and our team can be available on site to support those tests.

Depending upon the application requirement, we are able to offer a variety of alternatives to Disc Springs and Wavy Washers. Our Smalley Crest-to Crest®, Nested, Interlaced and Wavo® Springs each offer an alternative solution and have been successfully specified in many high load engineering applications. Please contact our technical team for more details.

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.