Welcome again to Smalley Talk. Our Smalley range of products are unique in their field and, although they have been a key range in our portfolio for over 35 years, we thought our readers might welcome an insight into the manufacturing method and its benefits.

If you have never heard of edgewound fasteners or are not familiar with the edgewinding process, you might want to keep reading. This little known but very interesting process is not even a topic included in the five million+ articles on Wikipedia!

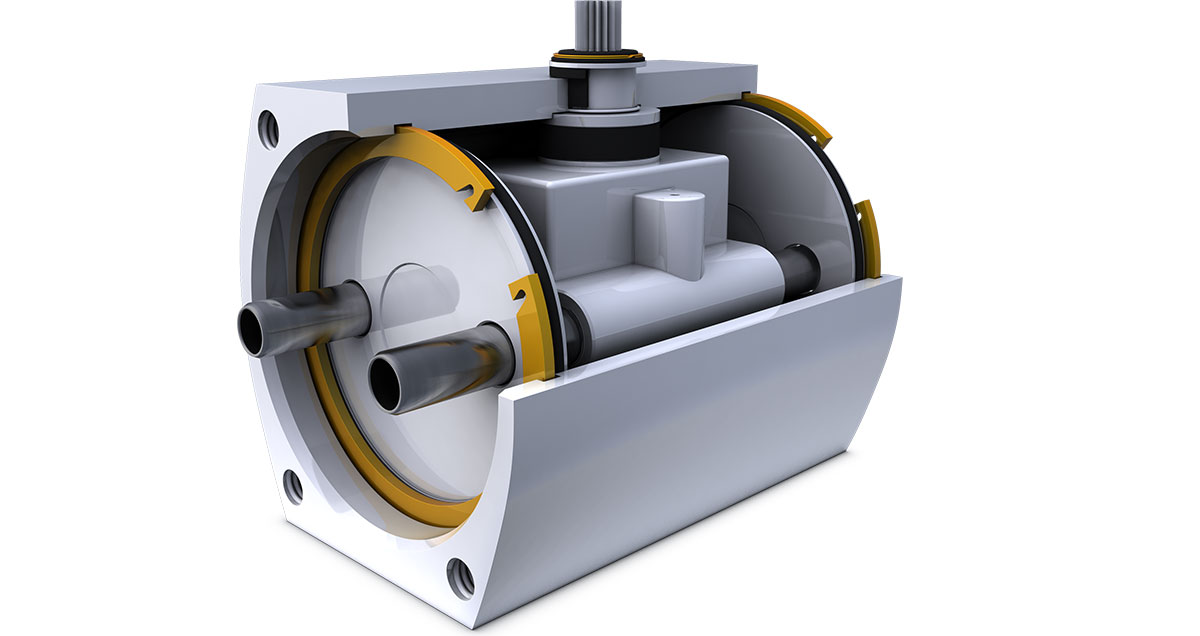

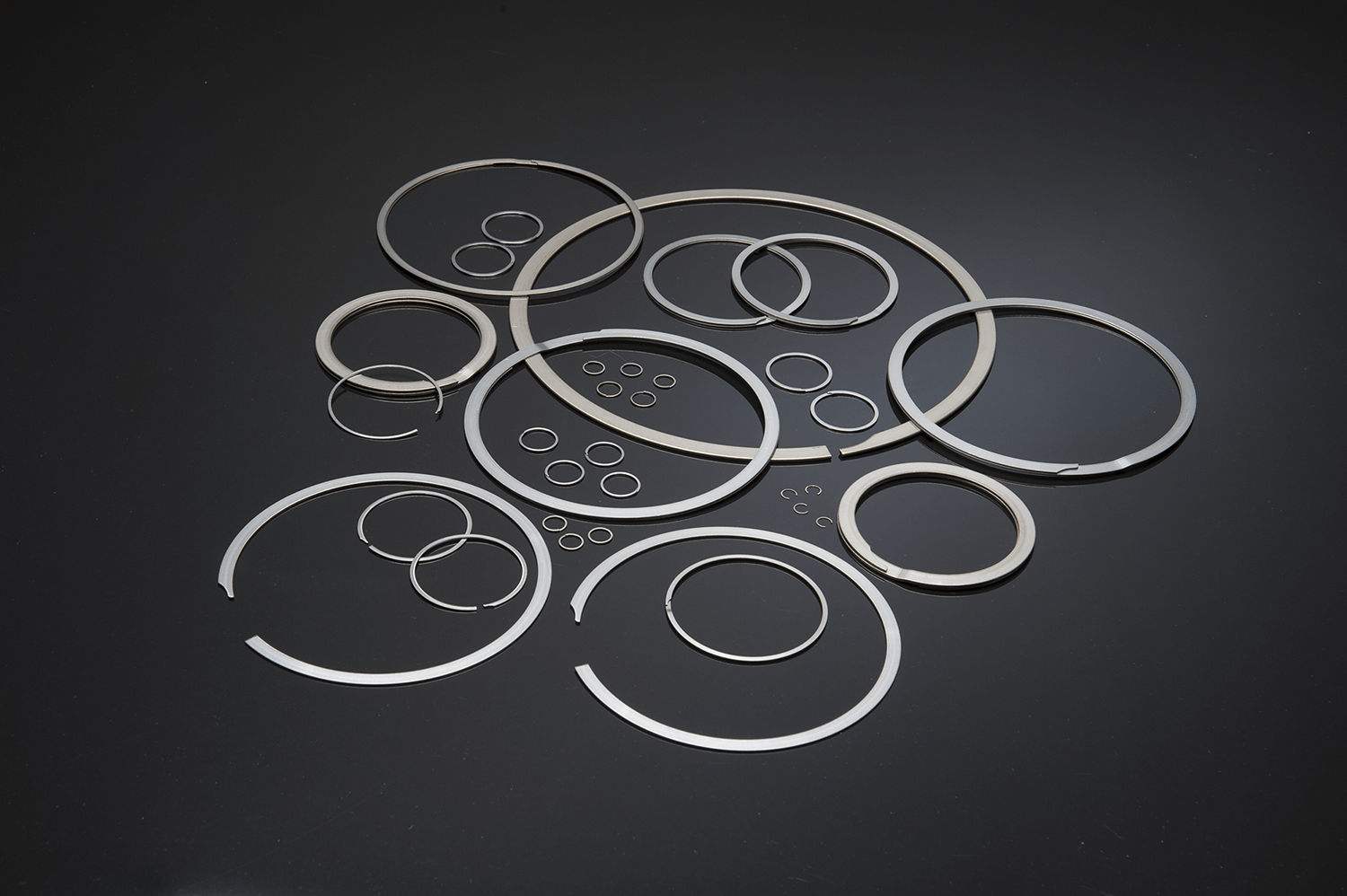

Over the past few decades, innovations in fastener manufacturing processes and technologies have helped shape this industry and the end products in which they are a crucial component. Edgewinding is one of those processes that has actually been around for many years and is typically used in manufacturing retaining rings (circlips) and flat wire wave springs.

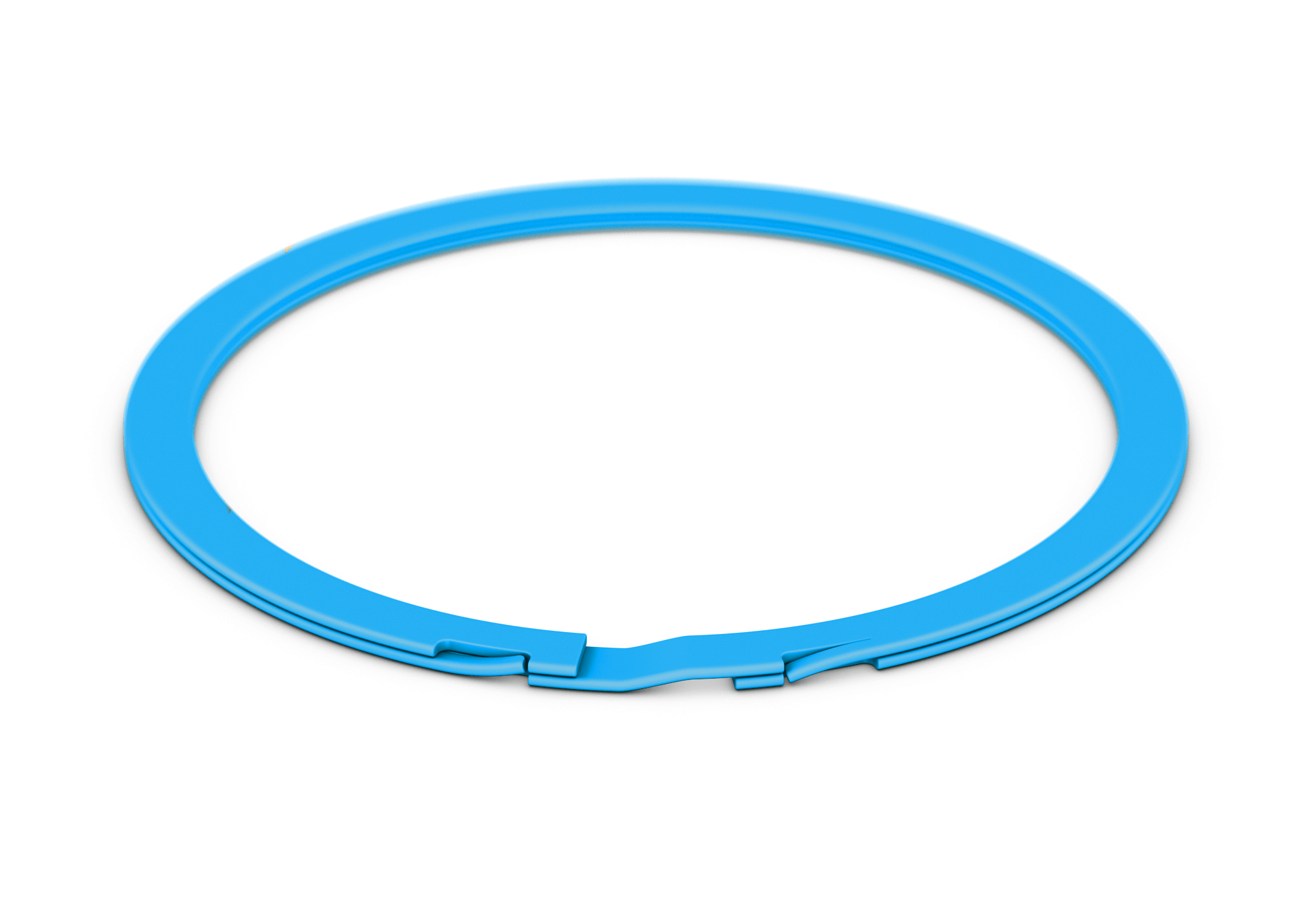

Edgewinding involves precision forming operations that coil pre-tempered flat wire on edge to create a near-perfect circle. The circular-grain metallurgy produced by edgewinding manufactures fasteners with strength and stability far superior to that of conventional stamped retaining rings and springs.

Developing the machinery and operational team it takes to successfully implement this process is no easy feat. Most retaining rings and wave springs are stamped – produced simply by stamping the part through the metal grain.

There are three key benefits that make edgewound retaining rings and wave springs a better solution than stamped parts.

1) The first is limited material waste. Edgewound rings and springs can be coiled to specific diameters with one or more turns layers or coils so there™s no material waste. This allows for the economical production of stainless steel and other exotic alloys.

2) Superior strength and predictability is another benefit. Edge-coiled fasteners created with flat wire make for rings and springs with metal crystallites having long axes going with the circumference (circular grain). This is in contrast with stamping parts from flat sheet metal, which makes the grains going straight through the part a less resilient material. Also, because Smalley products are cold rolled and not produced from annealed material, there is no heat treatment required after manufacture. This results in more predictable & consistent spring properties with every batch produced.

3) Quicker prototypes is the third key benefit. Edgewinding, also known as the ‘No-Tooling-Cost’ process gives manufacturing flexibility that allows our factory to make fine adjustments to a custom part quickly and efficiently. This allows customers to have production-grade samples for prototype testing faster than they thought possible.

In conclusion our Smalley edgewound retaining ring and wave spring products allow engineers to design components with endless possibilities in dimension, all with a quick turn-around time and superior quality. If you would like more information on our Smalley range please do not hesitate to contact our website or call our Technical Engineers, Simon or Justin for assistance

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.