In 1981 TFC formed a unique trading relationship with a little known US company, Smalley Steel Ring Company.

At that time, although well established within their own shores for almost half a century, the benefits that could be available to design engineers when space, weight and precision spring loads were a problem, was virtually unheard of this side of the Atlantic.

Thirty years later and with a sales growth 30 times 1980 levels, TFC is the leading supplier for the world’s number one manufacturer and development of Spirolox Retaining Rings and Spirawave® Wave Springs. With over 10,000 standard parts stocked in carbon spring steel and stainless steel as well as special designs in exotic alloys or customer specified dimensions, the philosophy built upon customer satisfaction through quality and service holds as true today as it did then.

The mainstay of sales growth revolves around the ability to supply, without tooling costs, fast delivery of prototypes and economical production.

A staff of TFC engineers are on hand to offer design consultations and provide customers with a full range of resources to ensure their application contains the most cost-effective solution.

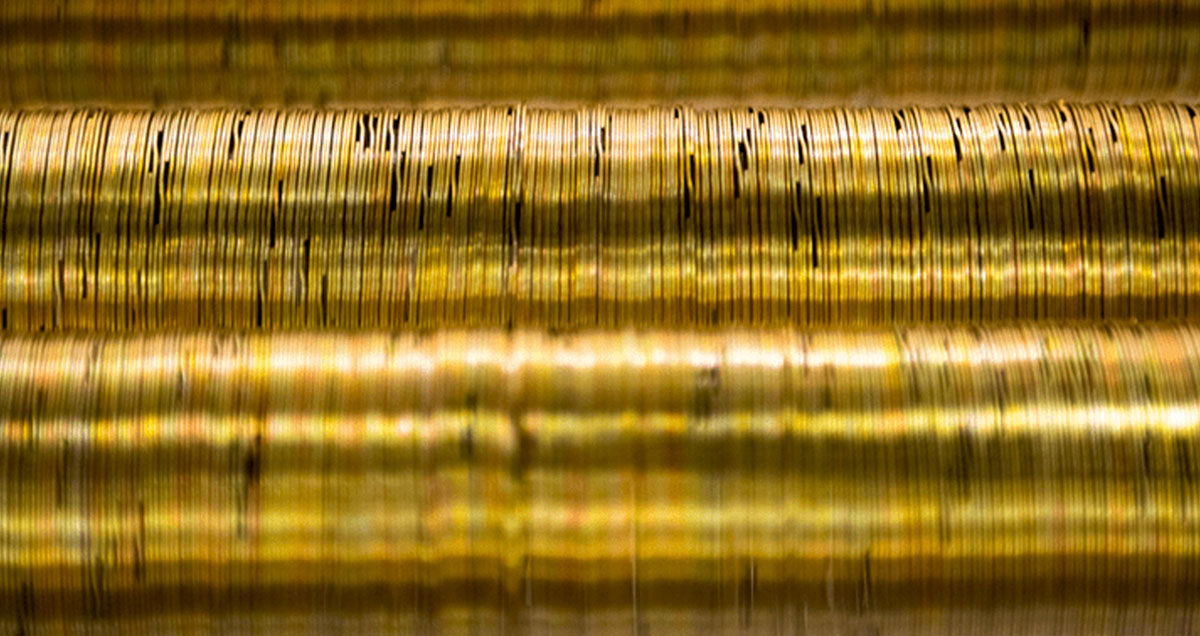

Smalley rings and springs are produced by edge-winding and have a circumferential grain structure that gives them exceptional strength, dimensional stability and predictable performance characteristics. Moreover, since there is no costly tooling involved, production times are greatly reduced and modifications at prototype stage can be made quickly and easily.

With an in-house rolling mill capacity capable of supplying virtually all of the manufacturing requirements, Smalley are able to supply in a wide range of standard materials including Carbon Spring Steel, AISI 17-7, 302 and 316 Stainless Steels as well as exotic alloys such as Inconel, Elgiloy, A286, Beryllium Copper and Phosphor Bronze.

Spirolox Retaining Rings

Advantages of Spiral Retaining Rings

- No gap full 360° retaining surface

- No Protruding lugs to interfere with mating components (uniform cross section)

- Economically produced in stainless steel

- Easy installation and removal

- No tooling charges on custom designs

- Available in a wide range of exotic materials and finishes

- Special end configurations to suit specific applications

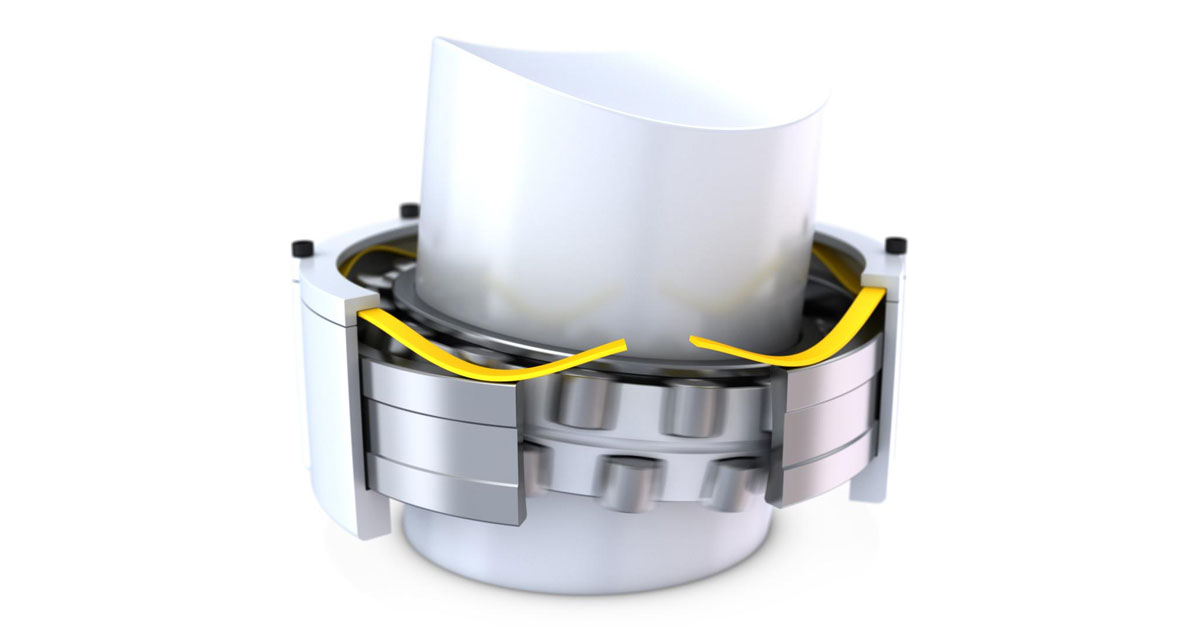

Crest-To-Crest Wave Springs

Wave Springs offer the unique advantage of space savings when used to replace coil springs. With their smooth, circular coiled sinusoidal wave form, and rolled round edges of pre-tempered wire, Smalley™s edge-wound Wave Springs offer many advantages:

- Reduced spring height by 50%

- Same force and deflection as coil springs

- Fit tight radial and axial spaces

- Over 4,000 standard sizes in carbon and stainless steel

- No Tooling Charges for special designs

- Exotic alloys for all environments

- Special end configurations to suit specific applications

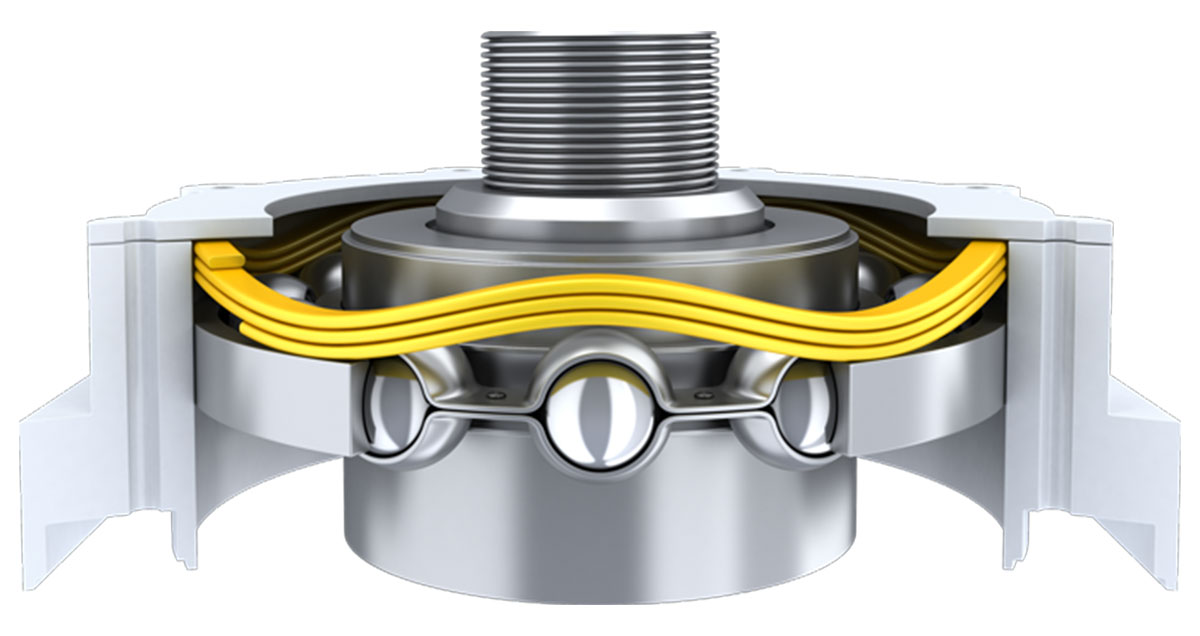

Laminar Sealing Rings

Laminar Sealing Rings are a metallic labyrinth seal consisting of multiple rings in a groove.

There are numerous configurations available which are produced from metal, not rubber, neoprene or other non-metallic materials and allows them to withstand high temperatures and corrosive environments.

Standard sizes are available from15mm to 1300mm and special seals are manufactured with No-Tooling-Charges.

For more information on the above products please visit the Smalley section of our website here

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.