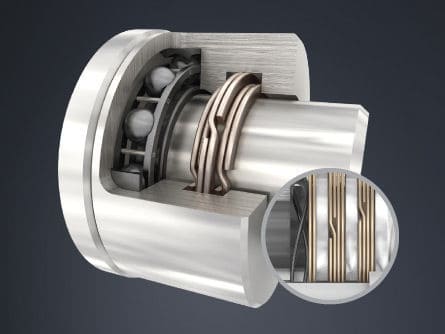

Smalley Laminar Sealing Rings is a metallic labyrinth seal consisting of multiple rings in a groove and are designed to prevent the ingress of dirt or splash liquid from contaminating components.

The arrangement of the Smalley Laminar Rings and the specific orientation of the rings are dictated by the application and severity of the environment. Since there is no friction with other rotating components, Smalley Laminar Rings are ideal for high speed applications.

Smalley Laminar Sealing Rings are often used as a primary seal or as an alternative means of sealing components in assemblies from contamination. Smalley offers several sealing ring configurations to accomplish this. Since they are produced from metal (not rubber or neoprene), Smalley Laminar Sealing Rings can withstand higher temperatures, more corrosive environments and other extreme conditions than common O-Rings or conventional rubber seals.

Like other Smalley products in the range, Smalley Laminar Sealing Rings are made by edge coiling pre-tempered flat wire and provide a low profile 360° sealing surface produced to exact dimensions and circularity. Since no tooling is involved, special designs and design changes can be easily accommodated without the need of expensive tooling.

Smalley Laminar Sealing Rings are readily available in a wide variety of materials including Carbon Spring Steel, 302,316 and 17-7 Stainless Steels, plus exotic alloys such as Inconel, Elgiloy, A286, Phosphor Bronze and Beryllium Copper.

For over 35 years Smalley has been manufacturing sealing rings designed to protect components in assemblies from outside conditions. The flexibility Smalley has in manufacturing (No-tooling-cost-process) allows virtually any size ring o be designed into an application at a reasonable cost.

There are 16 series of STANDARD Imperial and Metric Laminar Seal Ring configurations to select from. Eight of these series are sets consisting of single turn rings. The other eight series are sets consisting of double turn rings. Within each series are optical ring set configurations in both imperial and metric sizes. The selection of the appropriate set should be determined by the application. For some applications a complete labyrinth configuration is necessary due to a severe environment where contamination is highly probable. In other applications design engineers can keep the groove dimensions minimal by specifying laminar sets with rings clinging either to the bore or shaft.

Advantages of Laminar Sealing Rings.

- No friction with other rotating components and are ideal for high speed applications.

- Prevent dirt and splash water from contaminating components.

- When used in conjunction with other seals, Laminar Seals provide a primary seal against severe contamination, before the contaminants come in contact with secondary seal.

- Sets of multiple rings provide an efficient Labyrinth seal.

- Can be packed with grease for improved sealing capability.

- Rings may be produced from a wide variety of alloys to withstand more severe conditions including higher temperatures and corrosive environments.

- As a metallic mechanical seal they can out perform runner seals in durability and life expectancy.

- The change from rubber to metal reduces the need for frequent seal replacement.

- Occupies small radial and axial space.

Laminar Sealing Rings Product Catalogue

Need branded construction industry products with fast response and delivery to site? visit our sister company, Cavalier Fasteners Ltd

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.