Fluid Connectors For Automotive

Within the automotive industry, regulations are demanding more performance, smaller vehicles and new technologies. These developments are resulting in increased temperatures under the bonnet and higher fuel line pressures. When coupled with the need for improved speed and ease of assembly on the production line, the fuel connectors used need to be able to adapt.

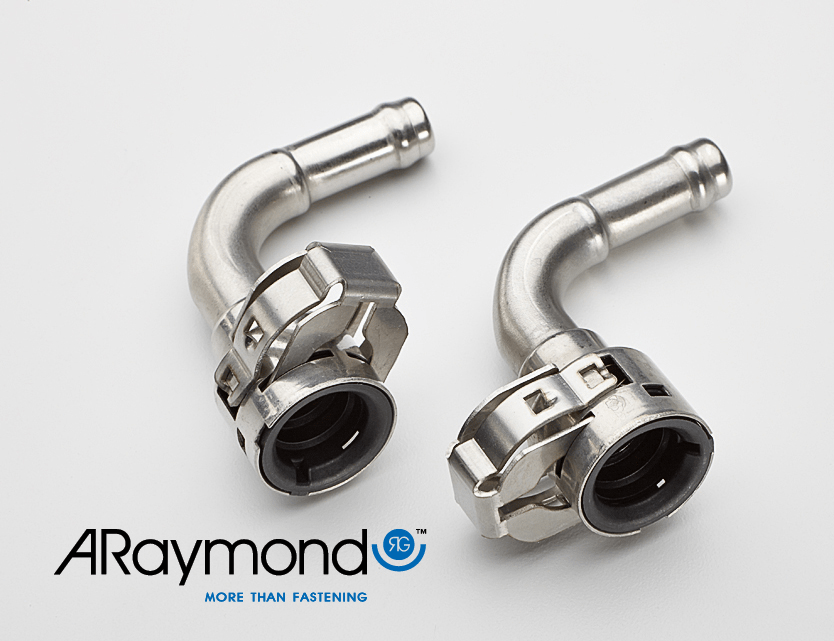

Our ARaymond plastic fluid Connectors have played a significant part in fuel line developments and the range has now been complemented with a Stainless Steel alternative – the Metal P2L® (Push to Lock). Different material, same practicality. The Push to Lock technology, or P2L®, as used in many of our plastic Quick Connectors, is appreciated for its solid benefits, particularly on the assembly line. This same technology has now been transposed to metal, with a similar design, offering the same strong features.

The design addresses the issue of incomplete insertion thanks to a visual indication of successful connection. Instead of relying on a secondary latch (like many connectors on the market), the ARaymond™ P2L® system relies on an integrated lock system. A simple push and a click announce the connection is made. As the locker will not latch until the mating end form is fully engaged, the

technology yields improved assembly quality. The absence of a secondary latch not only translates in a gain of time and energy, it also means less space is needed to accommodate the connector.

Another greatly appreciated feature is that no special tool is required to release the connection (while the locker is resistant to dislodgement), leading to significant gains during service operations.

With the advantages of metal Automotive manufacturers are now specifying metal to replace plastic in order to address the need for more robust connections, particularly in the truck market or hot engine compartments. The major

benefits of Stainless Steel are…

- Increased impact resistance – the Metal P2L® allows for better crash test performance, thus helping to meet increasingly demanding safety requirements.

- High-temperature performance and higher pressure performance – making it more suitable for a great number of contemporary fuel systems.

- Metal connectors can be formed to various angles as examples, 45 degree and 90-degree angles can be manufactured without the need for new moulds every time this configuration happens, offering increased flexibility.

Please contact TFC’s Quick Connector specialist for further details.

T: 01435 866011

E: sales@tfc.eu.com

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.