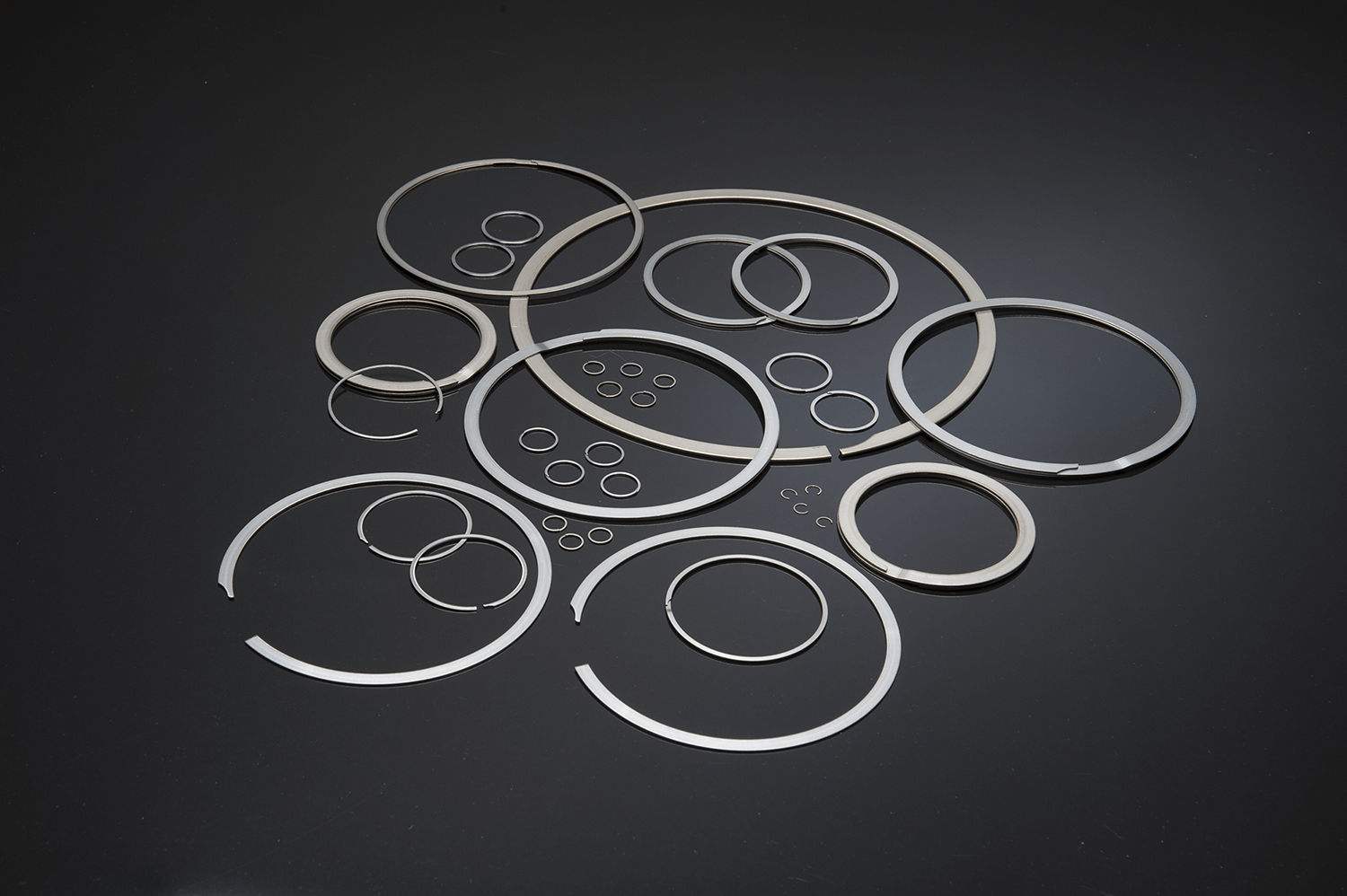

Welcome to TFC’s technical blog, where commonly asked questions are answered by our engineers. This time we are taking a look at Spirolox rings.

1. Do Spirolox Rings fit stamped ring grooves?

Yes, our Spirolox rings are designed to fit into grooves identical to those used for die-stamped circlips such as the Anderton, Seeger or Rotor Clip type products and, benefit the assembly by the absence of protruding lugs. We can supply an interchange listing for all our ranges or, alternatively, if you know the part number of the product you are currently using, we will be pleased to spec the appropriate Spirolox ring for your application.

2. How are your Smalley rings installed and/or removed?

Our spiral wound rings can be installed one of two ways: firstly by winding (spiralling) the ring into the groove where possible or, by pressing the rings axially onto a shaft or into a bore with the use of a tool that pushes them over a tapered mandrel or through a tapered funnel. This process can easily be automated for production assembly where high volume applications are involved. Removal of the rings is simple as no special tools or bespoke pliers are required. By using a simple pick or flat bladed screwdriver in between the ring’s removal notch and the groove, the ring can be simply wound out of the groove.

3. Can the retaining ring radial wall size be changed easily?

Yes, we can produce special designs with custom radial wall sizes because Smalley’s unique edgewinding process allows us to modify the ring properties without the need to modify expensive bespoke tooling as is the norm with traditional die-stamped circlips. When changes of this type are made, consideration needs to be given to material availability and stress-related issues associated with manufacture and installation. Our technical team are always pleased to offer the best design solution for your application.

4. What is the upper limit for retaining ring thickness?

The limit on the material thickness is relative to the diameter of the ring itself. There are two ways to increase the thickness of retaining rings: either by increasing the number of turns or by increasing the thickness of a single turn ring. To determine the optimal thickness we would like to understand your application and our technical team are on hand to review your requirements.

5. I am worried the gap/removal ends on a single turn ring will damage the cavity on my internal application. Can you create a closed ring, similar to a stamped ring, for the large cavity in my application?

If damaging the cavity is a concern, our multiple turn Spirolox rings can offer reduced contact with the mating surface this is one of the primary advantages of these types of ring. Since they are produced by coiling flattened round wire, unlike a die stamped circlip, the edge profile of the material is not sharp and, because the material thickness per turn is significantly less than a single turn ring, the installation forces are much lower. Also, we can supply modified end configurations that may help the desired ring performance.

For more articles like this one, take a look at our news page, or if you have your own question contact us and one of our engineers will be happy to help.

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.