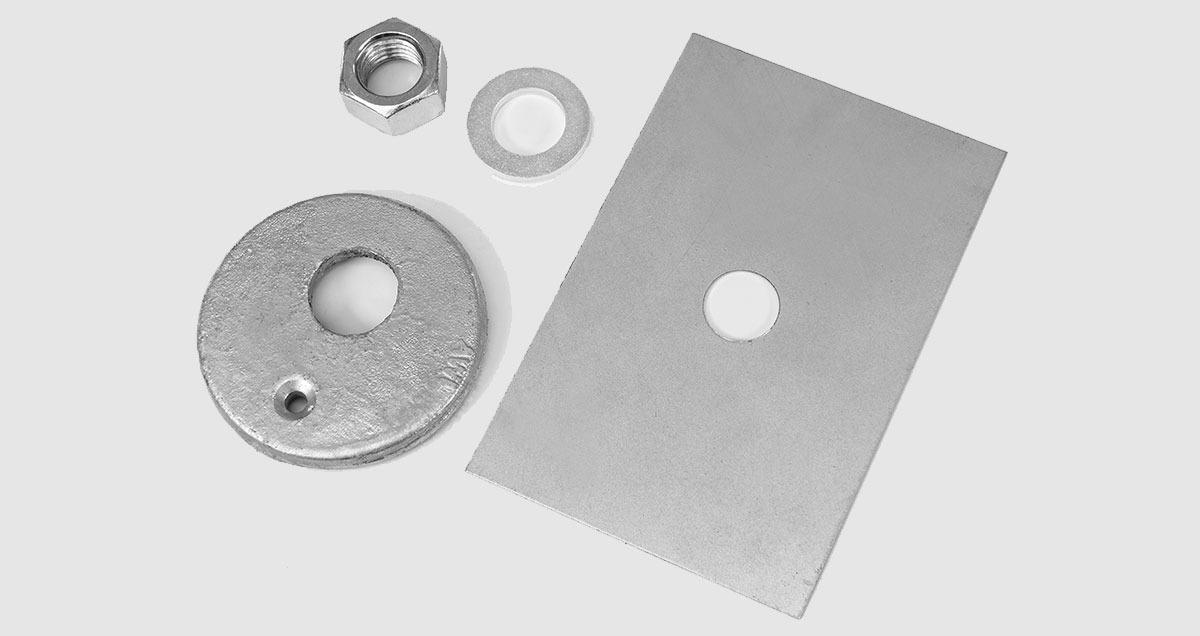

By utilising the total flexibility of the Smalley manufacturing process, it was possible to easily and inexpensively design a special 2-turn internal retaining ring for this tamper proof application. Ordinarily an internal retaining ring is supplied with a notch on the outer of the ring ends to facilitate removal. By reversing the notch profile (similar to that on an external ring) and by utilising a heavy duty material section, the ring is virtually impossible to remove.

The Smalley method of manufacture involves coiling flattened round wire to an exact diameter and, unlike conventional die-stamped circlips, does not involve any expensive tooling. Although there are many specific ranges of internal and external rings designed for Imperial and Metric standard grooves, this unique method of manufacture allows for the production of prototypes, small production runs and mid-life modifications to be accomplished easily and economically.

For further information click here

Please don’t hesitate to contact our expert team on 01435 866011 for further innovative engineering solutions.

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.