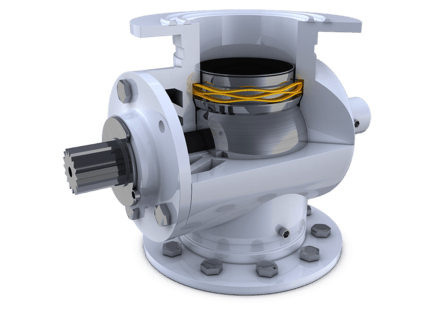

A Smalley Crest-to-Crest® wave spring was chosen to replace a series of small diameter helical coil springs previously used in this sealing application. By utilising the flat wire profile, the customer was able replace 12 single springs and their associated spring carrier with a single component. Furthermore, the open profiles of the flat wire spring was far less susceptible to clogging which would prevent the helical springs from functioning properly and lead to premature valve leakage and more downtime.

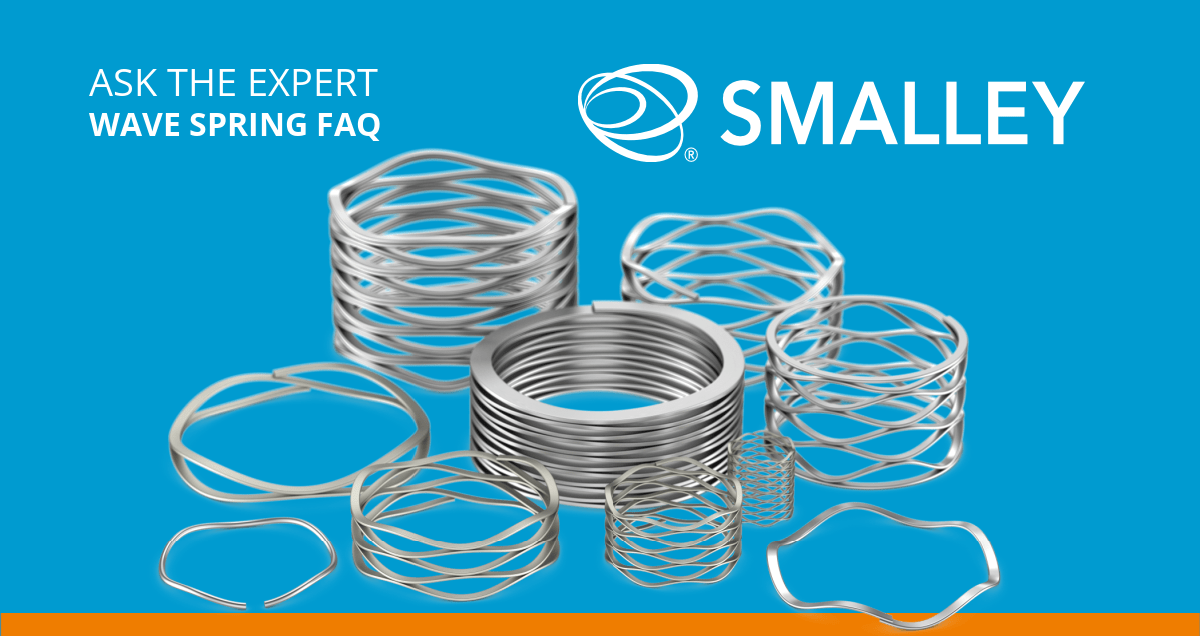

Smalley wave springs are precise flat wire compression springs that fit into assemblies where other springs cannot. Since the overall lengths and operating heights of wave springs are lower than those of conventional helical springs, they will often reduce the axial and radial cavity sizes by as much as 50%. This saving of space greatly reduces the assembly weight, raw material and machining costs allowing designers to greatly enhance the efficiency of their finished products.

For more information on TFC’s wave springs visit https://tfc.eu.com/pl/smalley_wave_springs_amp_retaining_rings or contact TFC’s engineering design team who are available to answer any technical questions call 01435 866011.

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.