Specialists in Vendor Managed Inventory Systems

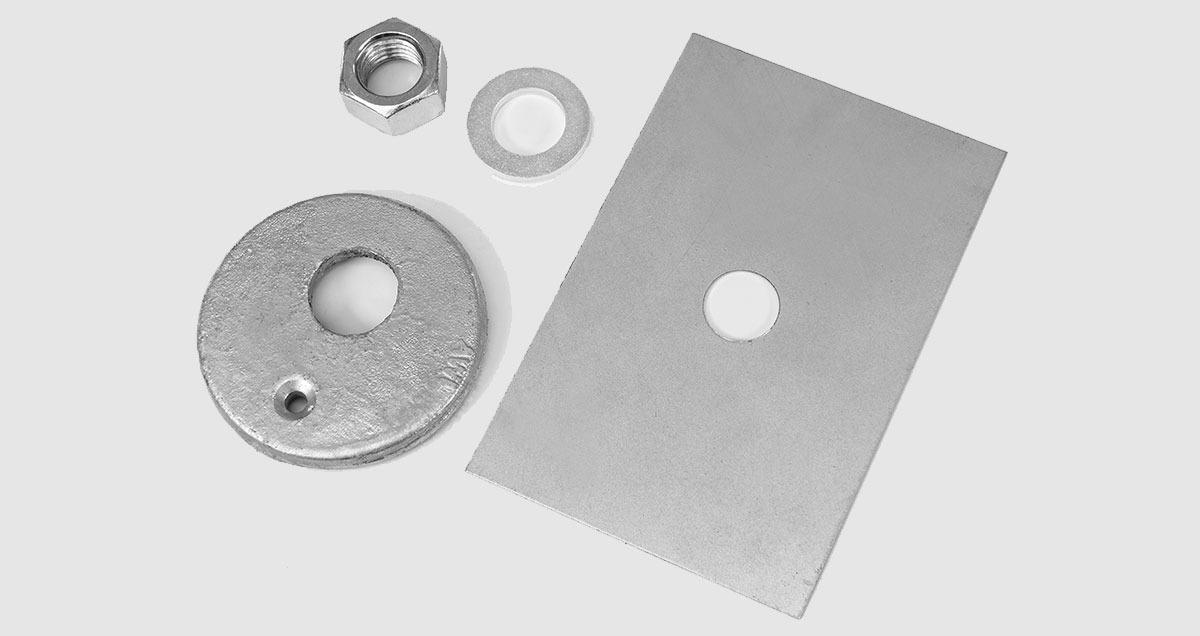

Our TFC Walsall branch specialises in Vendor Managed Inventory (VMI) systems, a wide range of part sourcing and supply chain solutions such as vending, kitting, and bagging, as well as providing high volume to drawing and machined parts for manufacturers in the Midlands from our global network of sources.

Our team are already supporting businesses across the Midlands, helping them to achieve production efficiencies and maximise profitability in their supply chain.

We can support your business needs, working closely with you to tailor our VMI service to your individual needs, ensuring:

- Your inventory levels are controlled;

- Your production lines keep moving and;

- You achieve cost savings.

We want our customers to experience exemplary customer service, procurement problem solving, predictable costs, and exceeded QA compliance levels. For over 50 years TFC have delivered this, along with the expertise to source and provide an expansive range of high-quality engineering fastener and fixing products to manufacturers.

To discuss your VMI requirements and arrange a site survey with our fully trained logistic specialists either call us on 01922 749940 or make a quick enquiry

Address: TFC Walsall, Unit L2 Lockside, Anchor Brook Industrial Park, Aldridge, Walsall, WS9 8EG

| Monday | 09:00 - 17:00 |

| Tuesday | 09:00 - 17:00 |

| Wednesday | 09:00 - 17:00 |

| Thursday | 09:00 - 17:00 Open now |

| Friday | 09:00 - 13:30 |

| Saturday | Closed |

| Sunday | Closed |

Vendor managed inventory (VMI) is a system where manufacturers outsource inventory management to a third party.

The third-party vendor takes full responsibility for the optimisation and management of the customer’s inventory. The vendor ensures that the right parts, fixings, consumables, material, and other products are delivered to the right locations at the right time, providing timely stock replenishment in-line with the predefined delivery schedule.

Look for a VMI partner that takes the time to understand your unique requirements, including material flow and the type and number of parts needed. A VMI system tailored to the exact requirements of your business will produce the best results.

When adopting a VMI system, remember that the service may need to evolve as the company grows. Choosing a VMI supplier that provides flexible VMI systems, good lines of communication, and access to a global market means that the partner can scale its service based on your needs, driving continuous improvement.

Vendor consolidation can significantly simplify inventory management. With TFC VMI, manufacturers will have a dedicated account manager, but will also benefit from the knowledge and expertise of a multi-disciplinary team.

TFC VMI allows manufacturers to:

- Streamline their supply chain through vendor rationalisation

- Continually monitor stock usage, allowing for adjustments as necessary

- Ensure continuity of supply, mitigating risk to the business

- Purchase parts for lower prices from the VMI provider due to its industry relations

- Reduce direct and indirect costs through process improvements and product standardisation

- Free up valuable warehouse & storage space & reallocate a workforce

- Manufacture quality assured products with full batch traceability knowing TFC have quality approved your requirements before supplying them

- Ensure end to end supply chain management

- Benefit from a VMI solution that is tailored to their specific needs

Specialists in Vendor Managed Inventory Systems

Our TFC Walsall branch specialises in Vendor Managed Inventory (VMI) systems, a wide range of part sourcing and supply chain solutions such as vending, kitting, and bagging, as well as providing high volume to drawing and machined parts for manufacturers in the Midlands from our global network of sources.

Our team are already supporting businesses across the Midlands, helping them to achieve production efficiencies and maximise profitability in their supply chain.

We can support your business needs, working closely with you to tailor our VMI service to your individual needs, ensuring:

- Your inventory levels are controlled;

- Your production lines keep moving and;

- You achieve cost savings.

We want our customers to experience exemplary customer service, procurement problem solving, predictable costs, and exceeded QA compliance levels. For over 50 years TFC have delivered this, along with the expertise to source and provide an expansive range of high-quality engineering fastener and fixing products to manufacturers.

To discuss your VMI requirements and arrange a site survey with our fully trained logistic specialists either call us on 01922 749940 or make a quick enquiry

Address: TFC Walsall, Unit L2 Lockside, Anchor Brook Industrial Park, Aldridge, Walsall, WS9 8EG

| Monday | 09:00 - 17:00 |

| Tuesday | 09:00 - 17:00 |

| Wednesday | 09:00 - 17:00 |

| Thursday | 09:00 - 17:00 Open now |

| Friday | 09:00 - 13:30 |

| Saturday | Closed |

| Sunday | Closed |

Vendor managed inventory (VMI) is a system where manufacturers outsource inventory management to a third party.

The third-party vendor takes full responsibility for the optimisation and management of the customer’s inventory. The vendor ensures that the right parts, fixings, consumables, material, and other products are delivered to the right locations at the right time, providing timely stock replenishment in-line with the predefined delivery schedule.

Look for a VMI partner that takes the time to understand your unique requirements, including material flow and the type and number of parts needed. A VMI system tailored to the exact requirements of your business will produce the best results.

When adopting a VMI system, remember that the service may need to evolve as the company grows. Choosing a VMI supplier that provides flexible VMI systems, good lines of communication, and access to a global market means that the partner can scale its service based on your needs, driving continuous improvement.

Vendor consolidation can significantly simplify inventory management. With TFC VMI, manufacturers will have a dedicated account manager, but will also benefit from the knowledge and expertise of a multi-disciplinary team.

TFC VMI allows manufacturers to:

- Streamline their supply chain through vendor rationalisation

- Continually monitor stock usage, allowing for adjustments as necessary

- Ensure continuity of supply, mitigating risk to the business

- Purchase parts for lower prices from the VMI provider due to its industry relations

- Reduce direct and indirect costs through process improvements and product standardisation

- Free up valuable warehouse & storage space & reallocate a workforce

- Manufacture quality assured products with full batch traceability knowing TFC have quality approved your requirements before supplying them

- Ensure end to end supply chain management

- Benefit from a VMI solution that is tailored to their specific needs

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Follow us